3D Scanning & Reverse Engineering

3D Scanning & Reverse Engineering

3D Scanning & Reverse Engineering Services in Mumbai & Across India

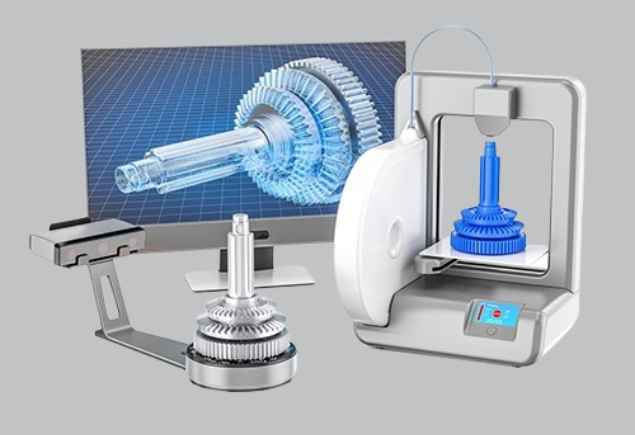

At Protomont Technologies we provide expert 3D scanning and reverse engineering services across Mumbai and India. Using non-contact laser scanners, white light scanning and advanced CAD tools we convert physical parts into detailed STL, STEP or IGES files ideal for reverse engineering, 3D printing or CNC machining. Our services support industries from architecture model making and industrial scale models to entertainment and real estate. Whether you’re rebuilding legacy parts or generating accurate miniature building models we deliver cost-effective, high-precision results.

Looking for low-cost 3D scanning or reverse engineering near you? Trust Protomont to recreate, redesign and deliver with accuracy.

3D Scanning

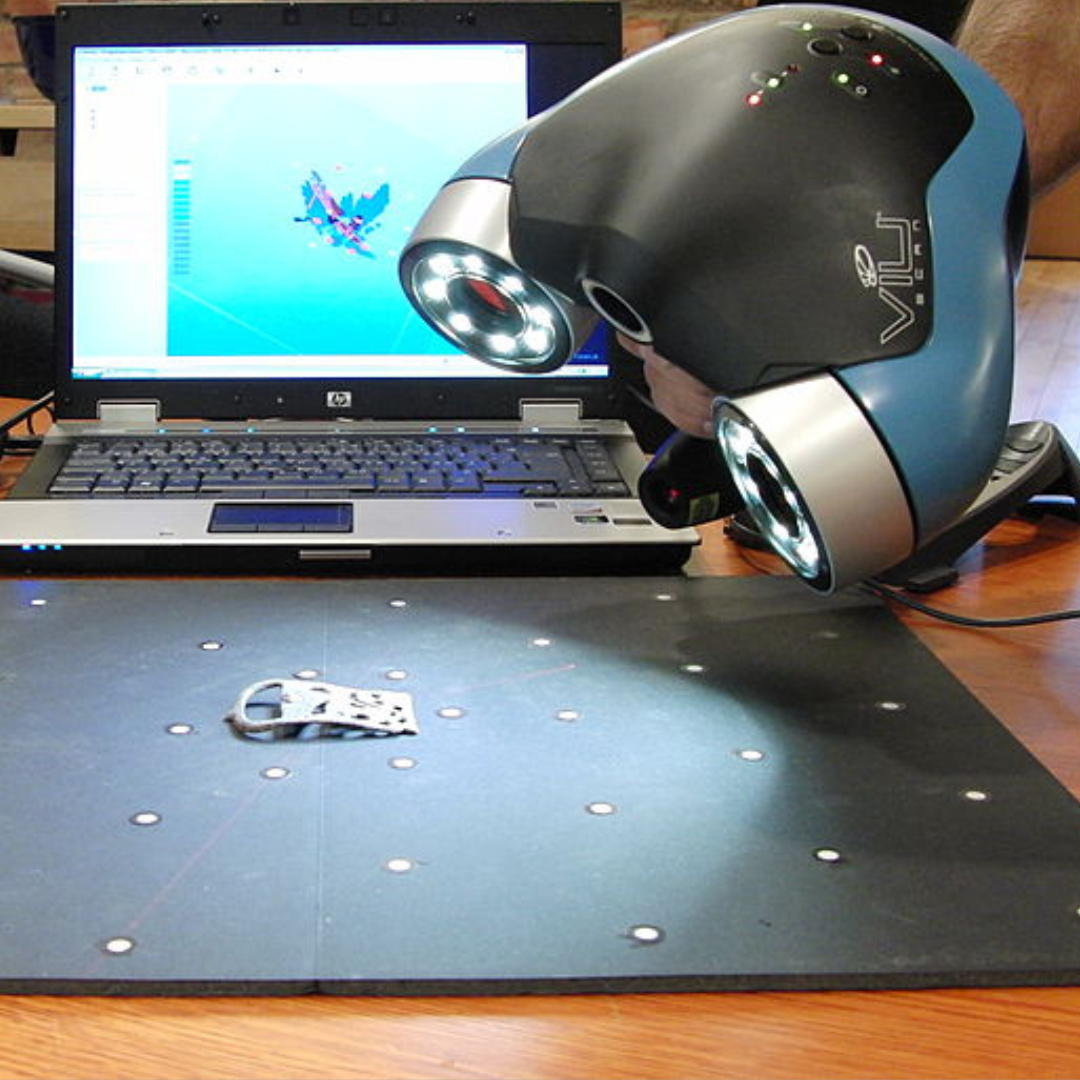

Expert 3D Scanning Services in Mumbai & Across India

At Protomont Technologies, we provide high-precision 3D scanning services in Mumbai and across India using non-contact laser scanning. We capture complex geometries to generate detailed STL, STEP or IGES files for reverse engineering, CNC machining or 3D printing. Trusted by industries from architecture to entertainment our low-cost 3D scanning services support real estate, manufacturing and scale model production. From scan to CAD modeling and miniature models, we help you move from object to digital prototype fast, reliable, and accurate.

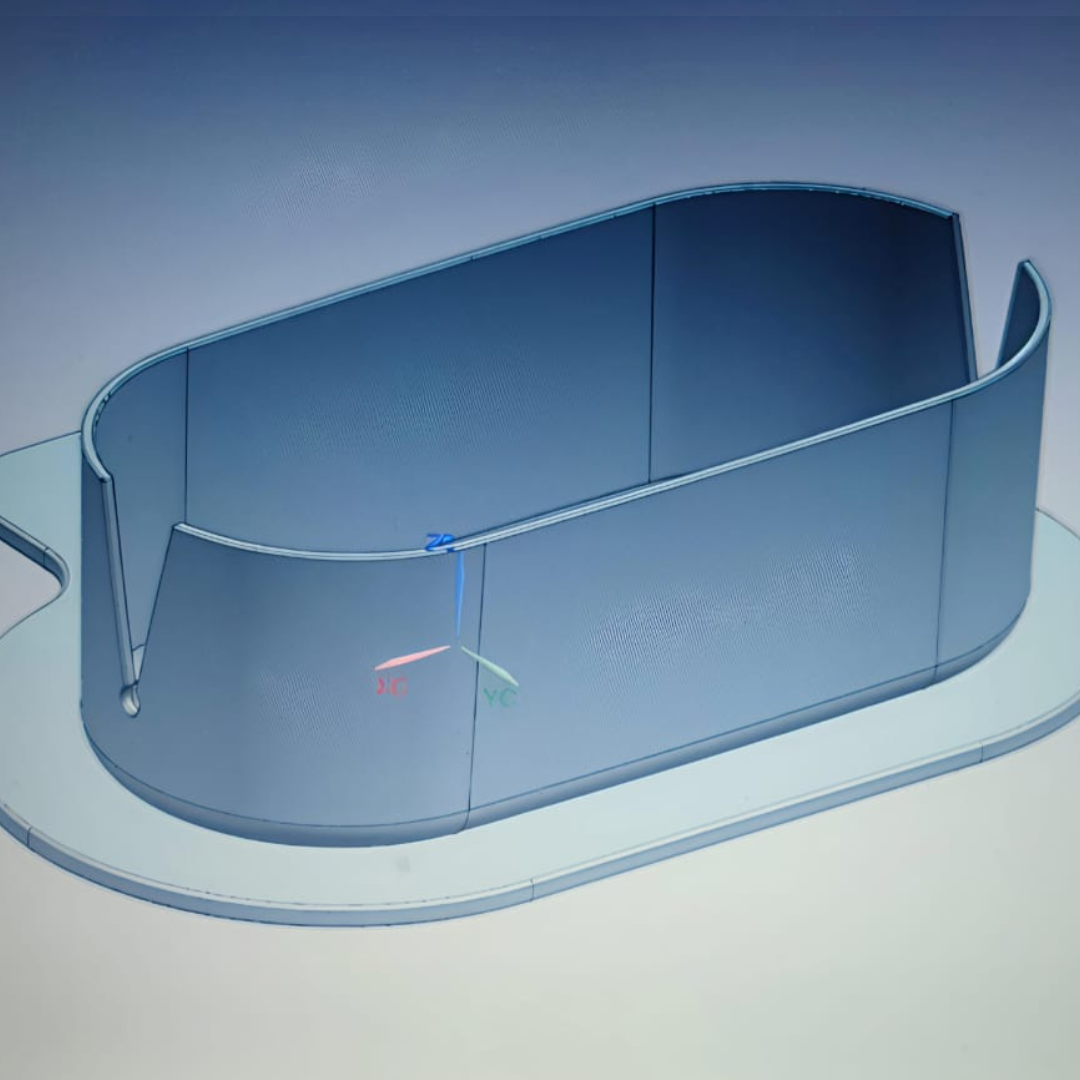

Reverse Engineering

Reverse Engineering Services: Rebuild, Redesign, Recreate

At Protomont Technologies, we offer expert reverse engineering services in Mumbai and across India. Using 3D scanners, CAD software, and white light scanning, we recreate accurate 3D CAD models from worn or undocumented parts. Ideal for architecture model making, industrial scale models, or miniature building models, our process supports product redesign, cost reduction, and legacy part recovery. From building model making to exhibition scale models, we help clients reimagine designs with precision, saving time and resources.