MELT3D M220 Dual Laser SLM Metal Dental 3D Printer

Contact Protomont Technologies

For product inquiries, technical consultation, or dealership opportunities:

Email: info@protomont.com

Phone: +91-9324898118

Website: www.protomont.com

By Protomont Technologies India’s Leading Provider of Metal Additive Manufacturing Solutions

The MELT3D M220 Dual Laser SLM Metal Dental 3D Printer is a next-generation Selective Laser Melting (SLM) system designed and developed by Protomont Technologies to meet the precision and productivity demands of the Indian manufacturing ecosystem.

Engineered for industrial applications in dental, medical, jewelry, aerospace, automotive, and engineering sectors, the MELT3D M220 combines high power, accuracy, and automation within a robust, production-grade architecture. With its dual 500 W laser system, large build volume, and permanent filtration technology, the M220 sets a new benchmark in metal 3D printing efficiency and reliability.

The MELT3D M220 is designed for organizations seeking industrial-grade metal additive manufacturing with uncompromising quality and minimal operational cost. Its dual-laser scanning system ensures high-speed printing and superior part uniformity across the entire build plate.

The system features a build volume of 220 × 140 × 100 mm, enabling the production of up to 300 dental crowns or 30 metal frameworks in a single batch. This exceptional throughput makes it ideal for large-scale dental laboratories, medical device manufacturers, and precision engineering firms.

Protomont’s proprietary Laser Following Powder Technology (LFPT) ensures real-time tracking of powder distribution, reducing single-layer laying time by approximately nine seconds and delivering up to 20 % improvement in printing efficiency compared to conventional SLM systems.

The printer’s permanent filtration system eliminates the recurring cost and maintenance downtime associated with filter replacement. With a lifespan exceeding 30,000 hours, this feature significantly lowers the total cost of ownership while ensuring operator safety and environmental compliance.

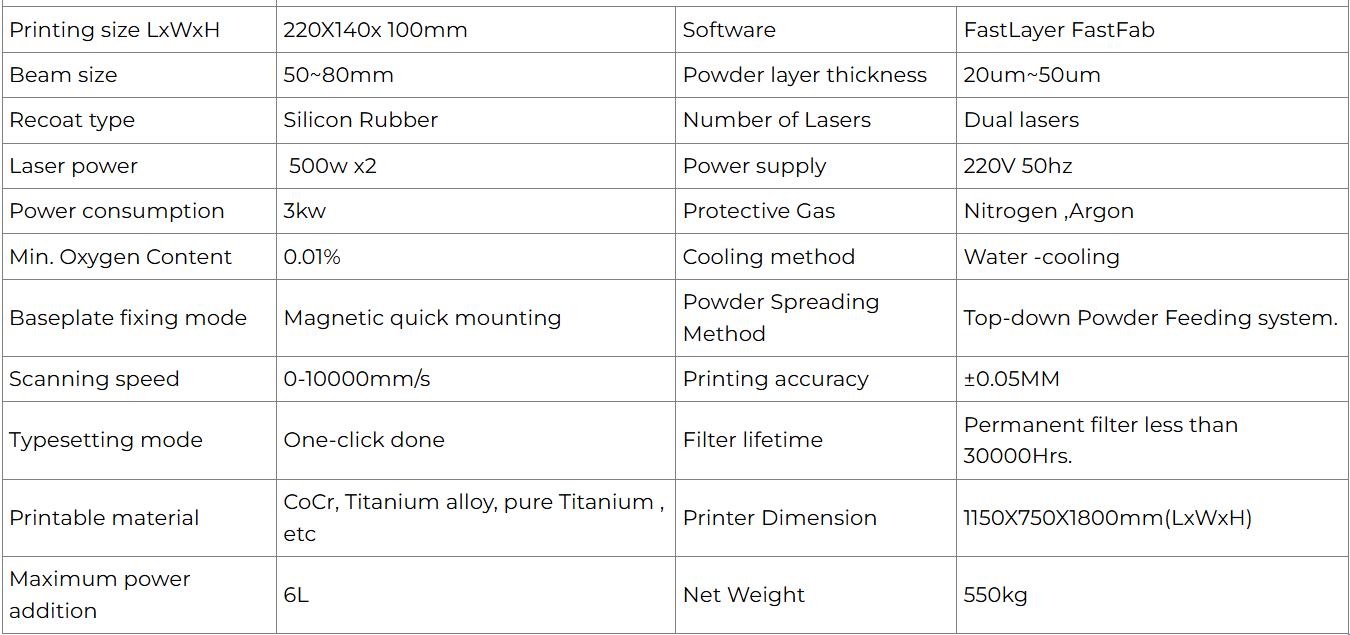

Key Technical Attributes

Dual 500 W fiber lasers for high-precision and high-speed printing.

Build size of 220 × 140 × 100 mm, supporting large production runs.

Permanent filtration system with a 30,000-hour service life—zero filter replacement and zero risk of misinstallation.

Layer thickness adjustable between 20 µm and 50 µm for fine resolution and surface finish.

Advanced powder spreading mechanism with silicon rubber recoater for consistent layer quality.

Magnetic quick-mount baseplate for simplified material change and maintenance.

Oxygen content maintained below 0.01 % using Argon or Nitrogen protection for superior material purity.

Water-cooled system for continuous, stable operation in industrial environments.

Accuracy of ±0.05 mm for repeatable, dimensionally stable parts.

Compatible materials: Cobalt-Chromium, Titanium Alloy, Pure Titanium, Aluminum Alloy, Stainless Steel, Nickel Alloy.

Intelligent Software Ecosystem

The MELT3D M220 is supported by Protomont’s in-house software suite, which has been developed to ensure complete control and ease of use throughout the additive manufacturing workflow.

MELT3D Layer

This intelligent slicing and layout software automates model preparation through one-click build setup and toolpath generation. It supports standard 3D design file formats such as STL, OBJ, STEP, CAD, and 3MF.

The software includes preloaded parameter libraries optimized for various metal powders, including dedicated settings for dental cobalt-chromium and titanium alloys. Advanced users can create and store custom parameters for specialized materials and geometries. Integrated print monitoring and automatic log generation allow full traceability of the production process.

MELT3D Fab

MELT3D Fab simplifies the operational workflow, guiding the user through setup, calibration, and printing with a logical, step-by-step interface. The process requires minimal training and can be mastered within minutes.

Built-in system diagnostics continuously monitor machine performance, while the intuitive user interface prevents configuration errors and ensures consistent print quality. The combination of MELT3D Layer and MELT3D Fab delivers a seamless, end-to-end digital manufacturing experience.

Workflow and Operational Efficiency

The MELT3D M220 has been engineered for seamless integration into industrial production lines. The combination of LFPT, permanent filtration, and automated software operation ensures a predictable, low-maintenance workflow.

Users can initiate printing through a single-click layout and start command, dramatically simplifying the setup process. The printer’s closed powder handling system enhances operator safety and maintains consistent powder quality.

Its modular design facilitates quick part removal, powder recycling, and equipment servicing. Combined with the water-cooling system and robust mechanical structure, the MELT3D M220 offers long-term stability under continuous production conditions.

Accessories and Auxiliary Equipment

Each unit is supplied with a comprehensive accessory package, including:

Stainless steel build plate and handling tools

Imitation silicone recoating blades

Maintenance and cleaning toolkits

Powder sieving system and nitrogen generator

Optional vacuum cleaner, powder drying oven, and heat treatment furnace

This complete ecosystem allows laboratories and factories to implement an integrated, start-to-finish metal 3D printing workflow.

After-Sales Support

Protomont Technologies provides end-to-end support throughout India, ensuring customers benefit from responsive service and operational continuity.

Support includes:

Installation, commissioning, and user training

Preventive maintenance and remote diagnostics

Rapid on-site technical assistance within 24 hours

Cost-price supply of core components and consumables

Lifetime access to software updates and parameter libraries

The company’s service infrastructure across major industrial hubs in India guarantees dependable post-installation assistance and technical expertise.

Why Choose Protomont Technologies

As one of India’s foremost providers of industrial 3D printing equipment, Protomont Technologies offers comprehensive additive manufacturing solutions, from machine installation to process optimization.

The MELT3D M220 embodies Protomont’s commitment to delivering high-precision, reliable, and cost-effective metal 3D printing systems tailored to the requirements of Indian manufacturers.

Key Advantages:

Dual-laser performance and consistent build quality

Permanent filtration with zero consumable replacement

Industry-specific parameter libraries for dental and medical alloys

Advanced Indian service network and rapid technical response

Local availability of spare parts and consumables

Compliance with global quality and safety standards

The MELT3D M220 is the preferred solution for enterprises seeking to adopt metal additive manufacturing in India with assured precision, performance, and profitability.

MELT3D M220 Dual Laser SLM Metal Dental 3D Printer:

Brand: MELT3D

Technology: Selective Laser Melting (SLM)

Build Volume: 220 × 140 × 100 mm

Laser Type: Dual 500 W Fiber Lasers

Supported Materials: CoCr, Titanium, Stainless Steel, Aluminum, Nickel Alloys

Key Features: Dual Laser, Permanent Filter, LFPT, High Accuracy ±0.05 mm, One-Click Workflow

Applications: Dental Frameworks, Titanium Implants, Jewelry Casting Masters, Aerospace Components

Dental Manufacturing

Developed with the specific requirements of dental laboratories in mind, the MELT3D FF-M220 enables efficient production of crowns, bridges, partial frameworks, and implant structures.

Its high build accuracy and dual-laser operation ensure precise fitting and optimal density in metal dental components. Integration with industry-standard CAD/CAM software such as 3Shape and Exocad allows laboratories to transition smoothly to in-house digital production, reducing outsourcing costs and lead times.

Medical and Orthopedic Devices

The system supports biocompatible metals such as titanium and cobalt-chromium, making it ideal for manufacturing orthopedic implants, surgical instruments, and patient-specific devices. The tightly controlled oxygen environment and stable thermal management ensure that printed parts meet stringent medical quality standards.

Jewelry and Casting

Jewelry designers and manufacturers benefit from the printer’s ability to produce intricate geometries and ultra-fine surface finishes directly in metal. By eliminating the need for wax casting and mold fabrication, the MELT3D FF-M220 accelerates design iteration and reduces material waste, enabling rapid creation of complex patterns and bespoke jewelry pieces.

Aerospace, Automotive, and Engineering

In aerospace and automotive industries, the MELT3D FF-M220 facilitates the production of high-performance components, including lightweight brackets, functional prototypes, and precision tooling inserts. Its dense and uniform metal parts meet the mechanical requirements for end-use applications. The system is also ideal for R&D institutions focused on materials research and component testing.