Polymaker™ HT-PLA White Filament – A New Era of High-Performance PLA

₹1,999.00 Incl. of all taxes

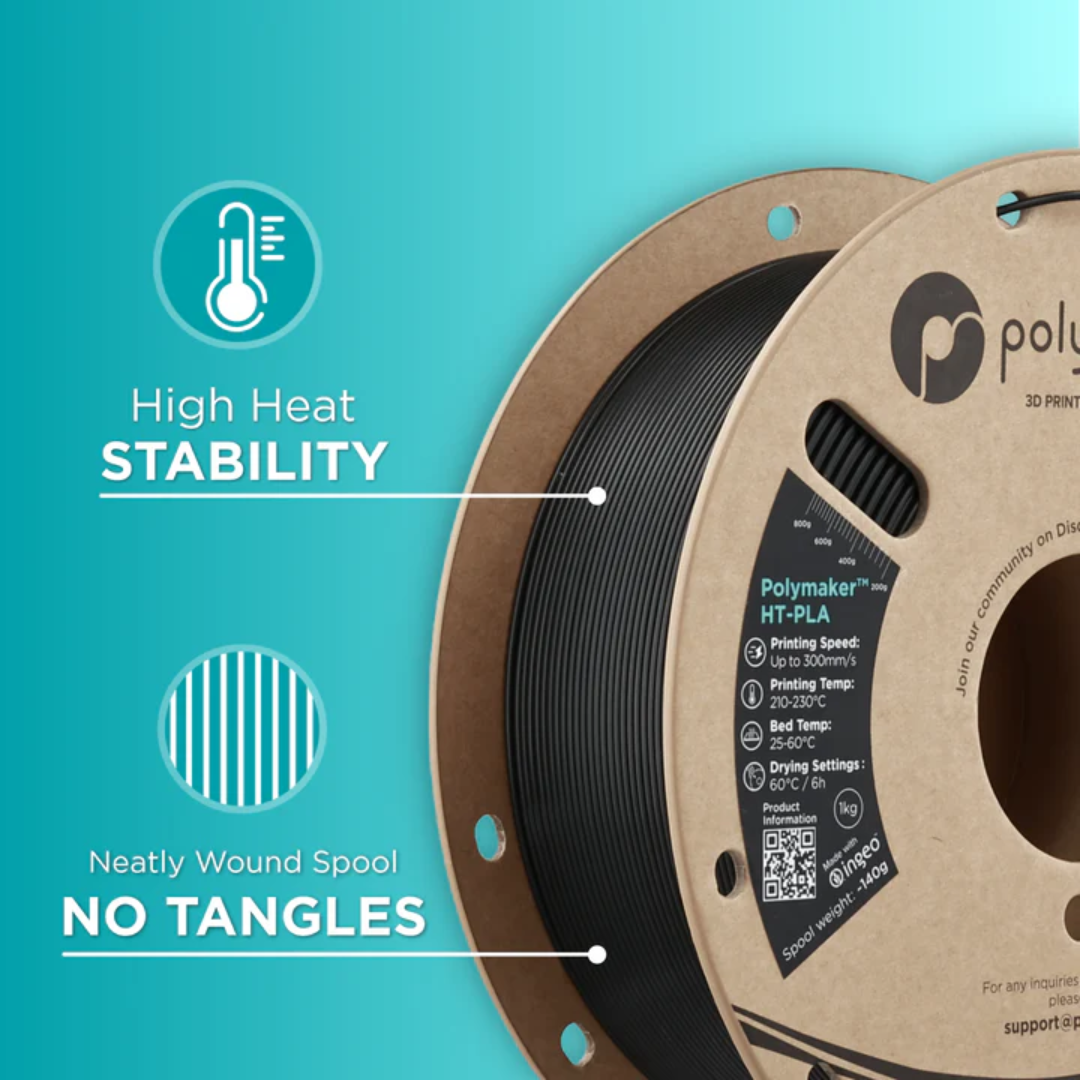

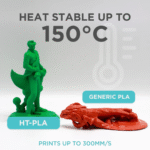

Polymaker™ HT-PLA white filament represents a major step forward in the world of high temperature 3D printing filament. Unlike traditional PLA, which softens at relatively low temperatures, HT-PLA is engineered to resist deformation up to 150°C when properly annealed. This makes it one of the most heat resistant 3D printing filament options available in the consumer and prosumer markets.

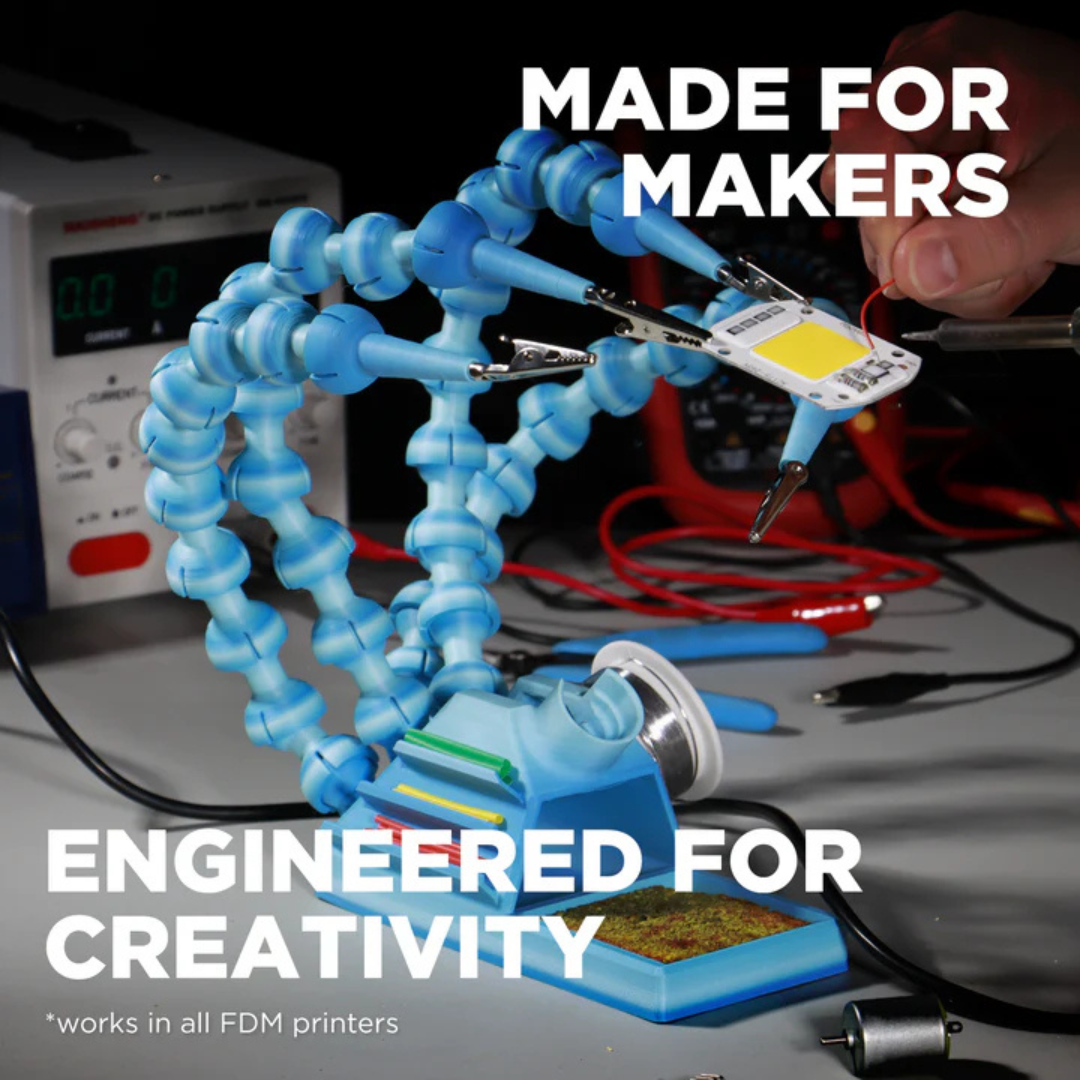

For makers, engineers, and researchers, HT-PLA provides the perfect balance: the ease of printing that PLA is known for, combined with engineering grade 3D printer filament properties normally reserved for advanced thermoplastics like polycarbonate filament, ABS filament, or even PEEK filament.

Why Choose Polymaker™ HT-PLA?

Exceptional Heat Stability

When comparing filaments using a filament heat resistance chart, Polymaker™ HT-PLA clearly outperforms standard PLA. With its ability to withstand up to 150°C, it rivals materials like ASA filament and nylon filament heat resistance while still offering the low-warping and easy bed adhesion of PLA.

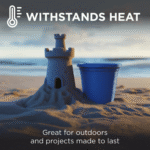

This balance is critical for applications where high thermal loads exist—such as functional prototypes, automotive parts, or enclosures for electronics.

Flawless Printability

Unlike advanced thermoplastic filament such as PEI filament (Ultem), PPSU filament (polyphenylsulfone), or PPS filament (polyphenylene sulfide)—which often demand heated chambers, high nozzle temperatures, and specialized equipment—HT-PLA prints on virtually any stock FDM 3D printer.

-

Printing Temperature: 210°C – 230°C

-

Bed Temperature: 25°C – 60°C

-

Speed: up to 300mm/s

Even older, less precise machines can handle this material when printing slowly, making it one of the most accessible heat resistant filament for 3D printing.

Eco-Friendly Engineering

HT-PLA retains the eco-friendly and biodegradable qualities of standard PLA, while adding mechanical and thermal performance. For users looking for food safe 3D printing filament, HT-PLA offers a safe option for certain non-critical kitchen tools and containers (though dishwasher use is not always recommended).

Compared to industrial 3D printing filament such as carbon fiber reinforced filament, metal filled filament, or glass fiber reinforced filament, Polymaker™ HT-PLA requires no hardened nozzle and causes minimal wear on equipment.

Material Composition

Polymaker™ HT-PLA is a PLA-based multiphase composite. The base resin is modified to enhance thermal stability while retaining the biodegradability of polylactic acid.

-

Biodegradability: Comparable to PLA

-

Hygroscopic Properties: Similar to PLA (store dry)

-

Abrasiveness: Non-abrasive (safe for brass nozzles)

For those requiring higher mechanical strength, Polymaker also offers HT-PLA-GF, a glass fiber reinforced filament with 12% glass fiber. This variant significantly boosts impact strength and stiffness, moving closer to composite filament 3D printing performance found in nylon carbon fiber filament or carbon fiber reinforced filament blends.

Annealing improves heat stability, allowing the filament to retain its form under extreme heat. While HT-PLA gains modestly from annealing, the GF variant achieves significantly higher HDT (Heat Deflection Temperature) values.

Comparisons with Other Filaments

PLA vs. HT-PLA

-

Standard PLA: Easy to print but low heat resistant filament for 3D printing (~60°C).

-

HT-PLA: Same printability but resists up to 150°C after annealing.

ABS Filament

ABS filament is a long-standing favorite for functional parts due to toughness, but it warps heavily and emits noticeable fumes. HT-PLA avoids warping and is odorless, while still offering high impact 3D printer filament properties.

ASA Filament

ASA filament is UV resistant and great for outdoor use. HT-PLA, however, has no inherent UV resistant filament properties. Future modifications may address this limitation.

Nylon Filament

Nylon offers excellent nylon filament heat resistance and toughness but requires high print temperatures and is highly hygroscopic. HT-PLA is easier to print and less moisture-sensitive.

Polycarbonate Filament

Polycarbonate filament provides unmatched impact strength and transparency, but requires very high nozzle temps (~280°C) and heated chambers. HT-PLA delivers engineering grade 3D printer filament qualities without demanding such equipment.

Advanced Thermoplastics (PEEK, PEI, PPSU, PPS)

-

PEEK filament and PEI filament (Ultem): Incredible industrial 3D printing filament, but expensive and machine-intensive.

-

PPSU filament and PPS filament: Highly chemical resistant filament, used in aerospace and medical fields.

-

HT-PLA: Not in the same extreme class, but offers a consumer-friendly alternative.

Specialized Applications

Functional Prototypes

HT-PLA is perfect for parts that need to endure high temperature 3D printing filament demands without specialized printers. Examples include:

-

Automotive interior components

-

Electronics housings

-

Tooling and jigs

End-Use Parts

With its food safe 3D printing filament qualities, it can be used for lightweight kitchen tools (cookie cutters, measuring spoons). However, thin-walled parts may warp in dishwashers.

Composite Upgrades

For tougher projects requiring structural strength, the HT-PLA-GF glass fiber reinforced filament competes with carbon fiber reinforced filament in rigidity. This makes it suitable for industrial 3D printing filament needs where cost efficiency is critical.

Specialty Filaments

While HT-PLA itself is not flexible, it pairs well with flexible filament (TPU / TPE) for dual-material printing. For electronics, conductive filament 3D printing may complement HT-PLA enclosures.

Limitations of HT-PLA

-

UV Resistance: Unlike ASA filament or UV resistant filament, HT-PLA is not ideal for prolonged outdoor use.

-

Impact Strength: Stronger than PLA, but not as durable as nylon carbon fiber filament or high impact 3D printer filament blends.

-

Chemical Resistance: Similar to PLA, not as robust as chemical resistant filament like PPSU.

-

Fire Resistance: HT-PLA is not inherently fire retardant filament.

Environmental and Safety Considerations

HT-PLA maintains the eco-friendly nature of PLA, being partially biodegradable. It also emits no significant fumes during printing, unlike ABS filament or polycarbonate filament.

Its biodegradability and low emissions make it a more sustainable choice compared to heavy-duty industrial 3D printing filament like metal filled filament or advanced thermoplastic filament.

Practical Guidance for Users

Best Practices

-

Always store filament in a dry box to prevent moisture absorption.

-

Use annealing to unlock maximum heat stability.

-

For HT-PLA-GF, switch to a hardened steel nozzle to handle glass fibers.

Printer Compatibility

-

Works with nearly all FDM printers.

-

No heated chamber required.

-

Compatible with 0.2mm nozzles for fine details.

Polymaker™ HT-PLA white filament is a breakthrough material that combines the printability of PLA with the strength and heat resistance of engineering grade 3D printer filament. While it does not replace ultra-high-performance materials like PEEK filament or PEI filament (Ultem), it stands as a cost-effective, user-friendly alternative for makers who need heat resistant filament for 3D printing without specialized machines.

Whether you are prototyping functional components, experimenting with composite filament 3D printing, or simply looking for a reliable advanced thermoplastic filament that performs in demanding environments, Polymaker™ HT-PLA is a smart choice.

It bridges the gap between eco-friendly PLA and industrial 3D printing filament, offering unmatched accessibility in the world of high-performance additive manufacturing.

| Category | Specification |

|---|---|

| Material Type | PLA-based multiphase composite (High Temperature PLA) |

| Color | White |

| Diameter | 1.75 mm (±0.05 mm tolerance) |

| Density | ~1.24 g/cm³ (typical PLA range) |

| Filament Class | High temperature 3D printing filament |

| Printability | Compatible with stock FDM/FFF 3D printers, no hardware modifications required |

| Printing Temperature | 210°C – 230°C |

| Bed Temperature | 25°C – 60°C |

| Print Speed | Up to 300 mm/s (HT-PLA-GF up to 350 mm/s) |

| Cooling Fan | ON (recommended) |

| Retraction (Direct Drive) | 1–3 mm at 20–40 mm/s |

| Drying Settings | 60°C for 6 hours (if filament absorbs moisture) |

| Annealing | 80°C – 100°C for 30 minutes (100°C recommended) |

| Heat Resistance (HDT) | Up to 150°C when annealed |

| Layer Adhesion | Moderate (not recommended for single-wall prints) |

| Shrinkage Rate | Very minimal, similar to standard PLA |

| Hygroscopic | Yes, similar to generic PLA |

| Biodegradability | Good, comparable to standard PLA |

| Abrasiveness | Non-abrasive (safe for brass nozzles); GF variant requires hardened nozzle |

| Food Safety | Similar to PLA – safe for certain applications, not recommended for dishwasher |

| UV / Weather Resistance | Not UV resistant (similar to PLA; further testing needed) |

| Fume Emissions | Low, comparable to PLA |

| Variants | Standard HT-PLA and HT-PLA-GF (glass fiber reinforced filament, 12% content) |

| Applications | Functional prototypes, jigs, fixtures, enclosures, light end-use parts |

| Strength Comparison | Stronger than PLA, less impact resistance than ABS filament or nylon carbon fiber filament |

| Eco-Impact | Lower environmental footprint than many industrial 3D printing filament types |