The Role of 3D Printer Dental in Modern Dentistry and Its Benefits.

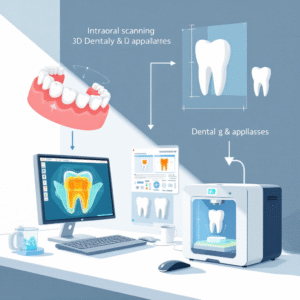

The integration of 3D printer dental technology is revolutionizing modern dentistry. By combining intraoral scanning with high resolution resin printing clinics and labs can now adopt fully digital workflows that enhance speed accuracy and patient outcomes. For example dentists can convert a scan of a patient’s mouth into a tangible model or custom appliance in house eliminating messy impressions and lengthy lab turnaround times. This seamless digital dentistry approach creates patient specific models surgical guides, crowns and orthodontic appliances with exceptional precision and detail. The result is a faster more cost effective practice that improves the quality of care and streamlines the dental workflow.

How 3D Printer Dental Technology Is Transforming Modern Dental Practice?

Digital technologies are reshaping every stage of dental care. In the past creating a crown or aligner required multiple manual steps. Today a dentist can scan a tooth and print the restoration on site. Intraoral scanners capture a patient’s anatomy in minutes and 3D printers turn the digital file into a model or appliance almost instantly. This transition to an end-to-end digital workflow reduces labor and material costs. For dental labs 3D printers take on heavy lifting they run complex jobs unattended produce dozens of appliances at a time and free skilled technicians to focus on finishing touches “digital workflows now allow dental practices and labs to produce custom appliances in a quicker and more cost efficient way. This requires less labor time and incurs lower costs than manual methods”

Digital technologies are reshaping every stage of dental care. In the past creating a crown or aligner required multiple manual steps. Today a dentist can scan a tooth and print the restoration on site. Intraoral scanners capture a patient’s anatomy in minutes and 3D printers turn the digital file into a model or appliance almost instantly. This transition to an end-to-end digital workflow reduces labor and material costs. For dental labs 3D printers take on heavy lifting they run complex jobs unattended produce dozens of appliances at a time and free skilled technicians to focus on finishing touches “digital workflows now allow dental practices and labs to produce custom appliances in a quicker and more cost efficient way. This requires less labor time and incurs lower costs than manual methods”

Custom implants and appliances 3D printing easily creates surgical guides splints and implant fixtures unique to each patient speeding up treatment. Dentists no longer need physical molds – they print guides for implant placement and aligners for orthodontics directly from scan data.

In house production Clinics can fabricate crowns dentures and night guards on site rather than sending impressions to an outside lab. This cuts down waiting times dramatically. In fact practices using 3D printers “can create appliances such as surgical guides and splints in house without the need to send impressions off to a lab and wait for them to be produced and delivered”

Improved lab workflows Dental laboratories adopting dental lab 3D printing see greater throughput. Multiple models or parts can be printed simultaneously on a single build plate meaning more work done in less time. With scans delivered electronically the total time from appointment to final product can shrink from weeks to days improving patient satisfaction.

By digitizing steps like impression taking and model fabrication 3D printer dental technology is fundamentally transforming how dentists and technicians work. The practice becomes more efficient and less error prone – for example fully digital production yields highly accurate models and restorations that match the patient’s anatomy exactly. In turn patients experience better fitting appliances and often require fewer adjustments or follow up visits.

Key Applications of 3D Printer Dental Technology

H3 Dental Models

One of the most common uses of 3D printer dental systems is making precise dental models. These models based on scans of a patient’s mouth enable clinicians to plan treatments and explain procedures. A printed model can be used for diagnostic purposes to simulate orthodontic movement or to design surgical guides. Because the printers capture every detail these replicas of teeth and gums are highly accurate enhancing case planning and patient communication. Other key applications include:

Orthodontic Appliances Custom aligners retainers and braces parts are manufactured from digital scans. 3D printing makes it easy to produce patient specific orthodontic appliances quickly. Practices using 3D printers can iterate orthodontic models faster and deliver personalized devices without outsourcing.

Crowns and Bridges Dental offices can now print temporaries or even final crowns in resin or wax. For instance a scanned preparation can be printed as a castable resin for a lab to invest and cast or as a precise wax model for pressing. This accelerates the turnaround for restorations.

Dentures and Partial Dentures Digital dentures – including full and partial – are gaining traction. After scanning the patient’s arches teeth and baseplates can be designed in software and printed directly. This streamlines what was once a multi visit process.

Surgical Guides Perhaps the biggest transformation has been in implant planning. 3D printed surgical guides tailored to each patient’s anatomy allow for minimally invasive and precise implant placement. According to industry experts printing custom guides “makes it possible to produce unique surgical guides splints and implants quickly and cost effectively”

Orthodontic and Sleep Apnea Splints Night guards and occlusal splints are easily printed in hard or flexible resins. Clinics can scan a patient’s bite and immediately print a temporary or final splint offering same day relief for bruxism.

Each of these applications demonstrates how digital dentistry and 3D printer dental systems combine. By printing dental appliances in house practices save time and reduce errors associated with analog workflows. Moreover specialized resins – from biocompatible surgical guide materials to durable crown and bridge resins – ensure that printed parts meet medical standards for strength and safety.

Benefits of 3D Printer Dental in Dentistry

Incorporating 3D printing into dental workflows brings speed precision customization cost efficiency and better patient care. Key benefits include:

Speed Faster Turnaround 3D printing dramatically cuts production time. What used to take days or weeks can now be done in hours. In house printing of appliances means patients leave sooner with their devices. As Dentsply Sirona observes adding a 3D printer “allows you to create appliances in house without the need to send impressions off to a lab and wait for them to be produced and delivered”

High Precision and Accuracy Dental printers use 20–35 micron resolution screens and even higher like 16K to ensure ultra fine detail. This precision yields very accurate models crowns and guides reducing the fit issues common with manual processes. Studies report that these printers can achieve precision levels matching or exceeding traditional lab methods.

Unlimited Customization Every dental case is unique and 3D printing excels at customization. Clinicians can adjust designs easily in CAD software and print a one off appliance that exactly matches patient anatomy. Whether it’s varying the thickness of an aligner or adding support structures to a bridge 3D printer dental systems enable tailor made solutions on demand.

Cost Effectiveness Once the digital setup is in place each printed part is relatively inexpensive compared to manual production. Digital workflows reduce the need for multiple material inventories and lower labor costs. For example 3D printing can significantly cut the cost of a dental lab’s production by automating routine tasks. One review notes that 3D printing “offers significant cost savings by reducing the need for labor intensive procedures and materials”. Clinics also save by printing more in house and minimizing outsourced services.

Improved Patient Outcomes Higher quality appliances and shorter treatment times lead to better outcomes. Patients benefit from fewer adjustments and less chair time. For instance scans sent to a printer or lab are more accurate than bite impressions which “makes finished products more accurate which frees up more time with fewer visits for the patient”. Ultimately patients receive optimal fitting restorations and appliances on a much faster schedule enhancing satisfaction and comfort.

Importantly 3D printing also enhances the patient experience. Patients appreciate seeing their digital scan turned into a tangible model or appliance and many experience quicker relief from issues like tooth loss or orthodontic corrections. The speed and precision of digital manufacturing can greatly reduce the anxiety and time typically associated with multi visit treatments.

Industry Innovations Driving Adoption

A confluence of innovations is accelerating the adoption of 3D printer dental technology:

Seamless Digital Workflow Modern systems integrate intraoral scanners design software and printers. Clinics are using chairside scanners to instantly capture patient anatomy and send the data to printers or labs. This end to end integration was once science fiction but is now standard. As Dentsply Sirona explains tools like 3D printers and scanners “are allowing dentists to adopt digital workflows which make practices more efficient and improve patient treatment outcomes”

Automated and Smart Printing Today’s printers include features like auto leveling remote monitoring and automatic resin refill. Multi point auto calibration and built in cameras further reduce manual steps. Automation makes 3D printing easy enough for any clinic – staff spend less time on setup and more on patient care. Modern printers exemplify the automation trend modular LCD panels fast resin handling and built in cameras let clinics print large dental models and appliances with minimal effort.

Advanced Materials Innovative dental resin materials are expanding what printers can make. There are resins formulated for virtually every dental application biocompatible surgical guide resins tough flexible resins for splints castable resins for crowns and bridges tooth colored resins for temporaries and more. These specialized materials meet ISO standards for intraoral use ensuring printed appliances are safe and durable. New biocompatible 3D printing materials let dentists fabricate end use devices not just models in house. Protomont’s Dental Resins section offers a range of these materials for everything from orthodontic models to crown casting.

High Resolution Printing The resolution of dental 3D printers keeps improving. What was once a 2K LCD is now 8K or 16K. Higher resolution means smoother surfaces and finer features on dental models and restorations. As printer resolution increases clinicians can trust that tiny margin details and tooth contours are faithfully reproduced.

Integration with CAD CAM Digital design software and 3D printers now speak the same language. Popular dental CAD programs export print ready files directly. This integration means designs for crowns dentures etc can go straight from digital model to resin tray without extensive file conversions. The convergence of scanning imaging and printing is making full digital workflows a reality.

Together these innovations mean modern dental teams can treat 3D printing not as a novelty but as a routine part of care. Automated user friendly printers fit easily into practice and lab routines. Meanwhile better materials and connectivity ensure printed dental devices meet clinical standards. In short ongoing R&D in printers scanners and resins is clearing the path for 3D printing in dentistry to become ubiquitous.

Why Protomont Technologies Leads in Dental 3D Printing

Protomont Technologies offers a comprehensive lineup of 3D printer dental solutions tailored for clinics labs and dental schools. We carry industry leading LCD DLP 3D printers and specialty dental resins backed by nationwide service and support. For example we stock large format printers such as the Jupiter SE and the new Jupiter 2 and Saturn DLP series as well as other trusted brands. Our LCD DLP 3D Printers category lets customers compare models side by side. We also supply all the consumables from model resins and surgical guide resins to castable and orthodontic resins – even color materials for tooth models. Protomont’s offerings include the latest printers and a full range of professional dental resins. Our customers benefit from large build volumes and ultra 16K resolution as in the Elegoo Jupiter 2 along with specialized biocompatible materials and reliable pan India support. What sets Protomont apart is our end to end support. We provide pre sales consultations to match a dentist or lab with the right 3D printer dental system. Our technical team offers installation and training plus prompt spare parts and accessories. With service centers across India customers get fast maintenance if needed. This full spectrum support ensures clinics can adopt digital dentistry confidently. Plus our competitive pricing and bulk supplies keep costs down for labs. In summary Protomont Technologies leads the market by combining:

Best in class equipment We offer high speed high resolution 3D printers like the Saturn DLP and Jupiter series plus all necessary peripherals wash cure stations milling accessories.

Comprehensive materials From our Dental Resin Materials collection labs can get any resin – model splint crown or guide – optimized for their printer.

Expert support Our team of engineers and application specialists guide customers through every step of digital dentistry adoption.

Pan India reach Nationwide service ensures dental practices in any city receive timely assistance.

Whether a small clinic or a large dental school customers trust Protomont for reliable dental 3D printing solutions. We continuously update our product line – for instance adding Elegoo Jupiter 2 16K 302×162×300 mm as soon as it’s available – so dental professionals always have cutting edge tools.

Ready to Transform Your Dental Workflow

With 3D printer dental solutions, the future of dentistry is here today. Imagine printing patient specific appliances overnight treating cases with greater accuracy and delighting patients with faster results. Protomont Technologies can help you make it happen. We invite dental clinics labs and schools to explore our range of printers and materials and discover how easy modern digital dentistry can be. Contact us now to upgrade your practice with advanced 3D printing technology. Protomont’s experts will guide you to the perfect system for your needs – complete with installation training and support – so you can focus on delivering exceptional dental care. Ready to experience the speed precision and innovation of 3D printer dental technology Visit our LCD DLP 3D printers section or Dental Resins section to see our offerings and get in touch today to start transforming your dental workflow.