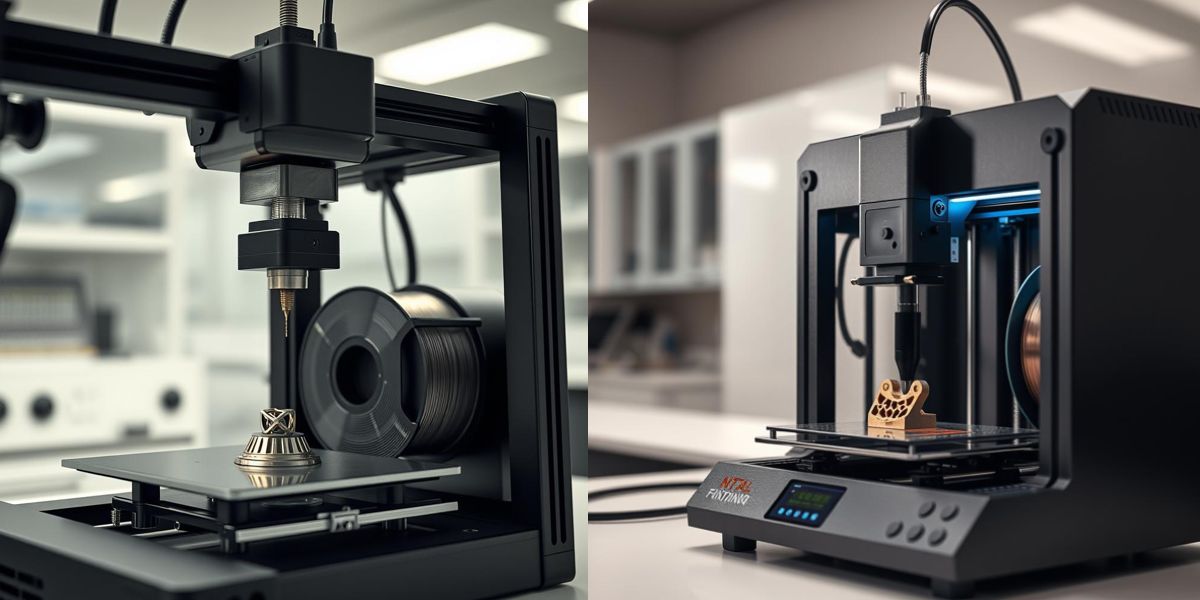

What Is the Tolerance of Metal 3D Printing and How Does It Affect Your Projects?

Metal 3D printing also called additive manufacturing builds parts layer by layer from metal powders or wires using high energy sources. Because each layer and material shrinks or warps slightly during building and cooling finished parts inevitably deviate from the ideal CAD dimensions. Tolerance quantifies this allowable deviation. It is the predicted range of possible dimensions for parts at the time of manufacture. In other words tolerance defines how closely the printed part must match the intended size. Accuracy is how close a part comes to the nominal size and precision is repeatability but tolerance is what you specify as acceptable. In metal 3D printing typical tolerances are on the order of a few tenths of a millimeter. Designers and engineers must account for these deviations in CAD and assembly. If tolerances are too tight parts may not fit or may require costly rework.

Metal parts made by additive manufacturing often have complex shapes. The dimensional tolerance is the allowable size error of these features. For example holes and bosses in a printed bracket will come out slightly different in diameter than the CAD design. Knowing the expected tolerance helps you size those features correctly and avoid assembly problems.

Typical Tolerances by Metal 3D Printer Process

Metal additive processes have different precision limits. In powder bed fusion with either laser or electron beam tolerances are usually specified as a percentage of part dimension or as an absolute value for a given length. For example many suppliers quote DMLS or SLM parts at roughly plus or minus 0.1 to 0.3 mm for most dimensions. In practice many DMLS or SLM parts achieve on the order of plus or minus 0.2 mm accuracy in each axis.

A summary of common metal processes is

- DMLS or SLM Laser Powder Bed Fusion – Approximate tolerance plus or minus 0.1 to 0.3 mm depending on part size. Some services cite plus or minus 0.076 mm in XY and plus or minus 0.152 mm in Z for the first 25 mm with an additional 0.1 percent per inch beyond the first.

- EBM Electron Beam Melting – Similar to SLM but usually a bit rougher with thicker layers. Accuracy is on the same order about plus or minus 0.2 to 0.3 mm though part geometry and cooling can cause larger variation. EBM parts often require post machining.

- Binder Jetting Metal – Tolerance about 0.5 percent of outer dimension typically on the order of plus or minus 0.05 mm once sintered. Binder jet parts have fine feature resolution and can hold small details but shrinkage during sintering means designers should expect dimensional error of around 50 microns.

- Directed Energy Deposition – Generally coarser with tolerance often plus or minus 0.5 mm or more due to larger melt pools and rougher surfaces. Used for large simple parts where tight tolerance is less critical.

In short metal additive manufacturing parts typically come out within a few hundred microns of nominal. This is much finer than typical plastic printing which often holds plus or minus 0.2 to 0.5 mm but still looser than a precision CNC machined part which can hold plus or minus 0.01 mm. Most powder bed metal printers operate between the realm of standard machining and fine machining tolerances. Designers should plan fits accordingly. For example if a hole is nominally 10 mm expect it to come out about 10.1 to 10.2 mm in the as printed state depending on orientation and process.

Factors That Affect Metal 3D Printer Tolerance

Several factors influence final accuracy

Material behavior – Metal powders expand and contract with heat. In DMLS or SLM builds the part expands slightly as it prints and then shrinks during cool down and heat treatment. Different alloys behave differently. Aluminum alloys can shrink 2 to 3 percent whereas stainless steel shrinks less. Powder reuse and distribution also matter. Modern systems use real time sensors and AI controls to adjust exposure on the fly minimizing these material effects.

Layer thickness – Thicker layers such as 50 to 100 microns speed builds but introduce stair stepping on slopes. Thinner layers improve accuracy in Z but cost time. Most SLM or DMLS machines run 20 to 60 micron layers for best detail.

Part size and geometry – Large parts tend to accumulate error. Thermal distortion is more likely in long or wide structures. Long thin walls or sharp corners distort more than chunky geometry. Hollow or lattice structures may deform if not supported well.

Build orientation – The orientation of a part in the printer affects accuracy. Vertical Z builds can stack layer to layer errors whereas horizontal orientation yields steadier XY accuracy. Engineers often print critical long dimensions in the XY plane or at a slight angle to balance stepping and stress.

Machine calibration and control – Laser focus power and scan strategy must be finely tuned. Even tiny misalignments or wear can shift dimensions. Leading operators perform frequent calibration and monitor chamber conditions to ensure each build meets specification.

Post processing – After printing parts undergo stress relief and support removal. Heat treatment can shrink or warp parts and cutting supports can distort edges. Binder jet parts shrink during sintering which is why designers allow tolerance margins. Finish machining such as milling or EDM may be required to meet critical dimensions.

Design and Project Implications

Tolerance directly impacts part form and fit. If you design mating components such as a shaft and hole you must include clearance or interference offsets in CAD. For a sliding pin fit you may add at least 0.3 mm clearance for metal additive manufacturing. For tight press fits even with zero clearance there may be a few tenths of millimeter overlap due to tolerance error.

For assemblies uncontrolled tolerance stack up can cause failures. In aerospace and medical sectors tolerances are often specified below plus or minus 0.1 mm. To meet this many providers print near net shape and then machine critical features. For less critical parts sanding or reaming may be sufficient to achieve the required dimension.

Most manufacturers run a first article inspection on metal prints. Parts are checked visually and dimensionally with gauges and higher end services use CMM or CT scanning. These reports confirm accuracy and allow adjustment of CAD or build strategy if needed. Tighter tolerances usually mean more time and cost due to slower printing finer layers extra supports and more inspection. Designers should always ask providers for both as printed tolerance and post machining options.

Protomont Technologies Metal 3D Printer Capabilities

At Protomont Technologies we use advanced metal additive manufacturing systems to deliver high precision parts. Our DMLS and SLM printers feature multi laser setups closed loop controls and fine layer resolution enabling repeatable industrial performance. In 2025 we have also integrated real time monitoring and AI feedback so that each layer is adjusted to minimize deviations.

We support a wide range of metals including stainless steels titanium aluminum nickel based superalloys and tool steels. For many alloys the as printed accuracy is around plus or minus 0.3 mm for the first 100 mm of dimension. Stainless and titanium parts typically meet plus or minus 0.3 mm in XY by process design. Where customers need tighter precision we can achieve plus or minus 0.1 to 0.2 mm by optimizing build parameters or applying post machining. We also provide inspection services with CMM or CT and supply detailed reports when required.

By knowing and communicating these capabilities our clients avoid surprises in assembly. When you design with Protomont you can specify critical dimensions and we advise how to model them with proper clearance. For demanding tolerances we combine DMLS printing with CNC finishing to achieve both design freedom and high accuracy.

Metal 3D printing delivers excellent design flexibility but every process has finite accuracy. Typical powder bed prints hold dimensions within plus or minus 0.1 to 0.3 mm. Achieving this requires control of materials lasers and post processing. The key impacts on projects are ensuring enough clearance for mating parts allowing for shrinkage and planning inspections.

By understanding tolerance limits you can design features such as holes fits and assemblies that will work as printed. Partnering with an experienced provider like Protomont ensures guidance on material selection print setup and finishing to reliably meet targets. Always specify critical dimensions include safety margins in CAD and request first article checks. With these steps metal 3D printing becomes a reliable production tool instead of a source of fit issues.