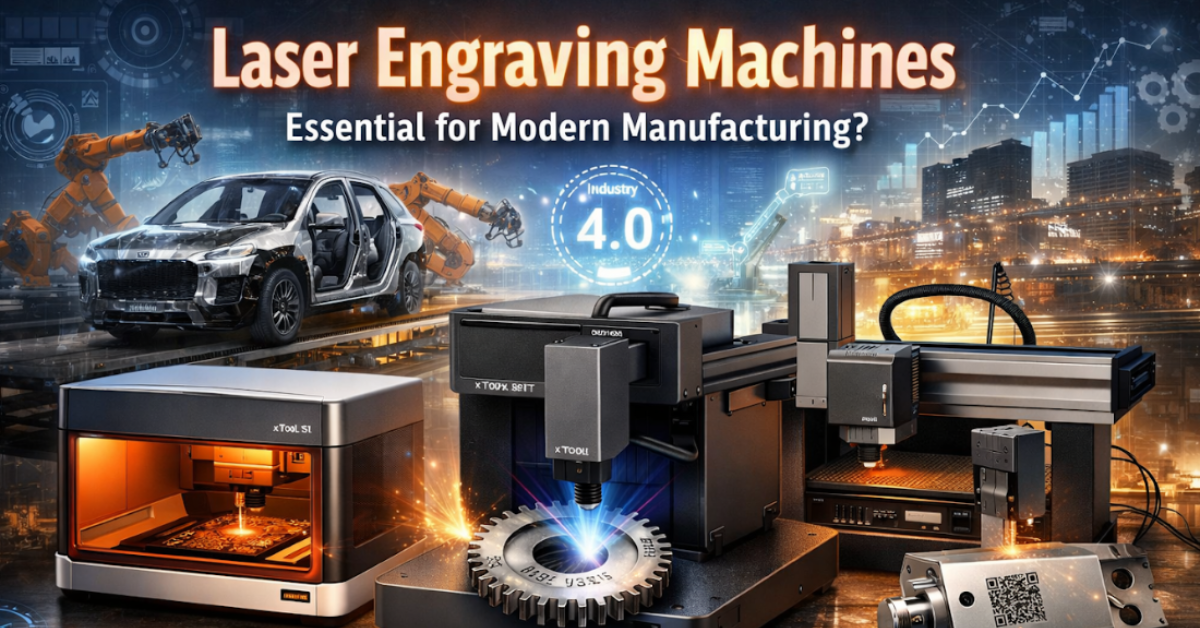

Why Laser Engraving Machines Are Essential for Modern Manufacturing?

Modern industry demands ever higher precision efficiency and flexibility. Laser engraving machines answer these needs by providing non contact high speed marking across a wide range of materials. As Indias manufacturing sector embraces Industry 4.0 and automation lasers are powering a new era of precision speed and quality from automotive to electronics and signage. Laser systems enable manufacturers to achieve micron level detail and durable marks that are critical for traceability branding and customization. Protomont Technologies LLP a trusted supplier of industrial laser solutions in India offers a full lineup of professional engravers CO2 fiber and diode lasers to meet these demands.

Key advantages of laser engraving Machine include

Unmatched Precision

Laser beams can be focused to micron sized spots producing extremely detailed and repeatable marks. This precision is vital for microelectronics medical devices and aerospace parts where fine text or logos are required.

High Speed and Throughput

Lasers engrave much faster than mechanical methods. A typical laser adds serial numbers or logos in seconds avoiding bottlenecks in production. Quick cycle times boost productivity in high volume manufacturing.

Broad Material Compatibility

Modern lasers cover virtually any material. CO2 lasers work on wood acrylic leather fabrics and glass. Fiber lasers etch metals stainless steel aluminum brass etc with high contrast. Compact diode lasers can handle plastics coated metal wood and more. This versatility means one tool can serve multiple production lines.

Cost effectiveness

Lasers minimize consumables and waste. There is no need for inks or chemicals and alignment and wear issues are reduced. Over time this lowers operating costs despite a higher initial price.

Automation Friendly

Laser machines integrate easily with automation. They can operate under computer control or PLCs run conveyor fed parts and require minimal operator intervention. Fully programmed lasers free workers for other tasks.

Permanent Tamper Proof Markings

Laser marks are durable and cannot be smeared or corroded off ensuring that crucial data like batch codes or regulatory labels remain legible for the products life.

Together these benefits make laser engraving an indispensable technology for todays manufacturers. In the next sections we examine laser types and how they solve real world challenges like traceability customization and automation in industrial settings.

Types of Laser Engraving Systems

Laser engraving comes in several technologies each suited to different materials and applications. Protomont supplies all major types diode CO2 and fiber so manufacturers can choose the right tool for the job.

CO2 Lasers

Use a carbon dioxide gas laser to process organic and non metallic materials. They excel on wood acrylic glass plastic and leather. CO2 systems are widely used for cutting and engraving signage packaging textiles and decorative art. For example xTool CO2 cutters like the xTool P2 55W can cut thick wood or acrylic sheets and engrave large area patterns. CO2 lasers have longer wavelengths which are absorbed by non metals but pass through most metals.

Fiber Lasers

Use a fiber optic laser to engrave metals and some plastics. High power fiber lasers mark stainless steel aluminum brass titanium and coated metals with high contrast. They are popular in automotive electronics aerospace and tool marking. For instance the xTool F2 Ultra 60W MOPA fiber laser can produce multi color engravings on stainless steel. Fiber lasers are valued for ultra fine spots and long lens life with no gas refill needed.

Diode Lasers

Use solid state laser diodes to mark a variety of substrates. Diode lasers are more compact and energy efficient. They typically range from a few watts for small engraving tasks up to 40W in enclosed systems. Protomonts xTool S1 40W diode is an example an enclosed desktop engraver that safely and rapidly etches wood plastic leather and even metals with special coating. Diode systems like xTool F1 10W or Snapmakers modules are often used in small shops schools and laboratories for on site customization.

By offering all these types Protomont ensures manufacturers can mark any material from plastic housings to hardened steel tools with the best technology.

Solving Manufacturing Challenges with Laser Engraving

Laser engravers directly address several key production challenges.

Traceability and Compliance

Modern quality standards automotive aerospace pharma etc require permanent marking of serial numbers lot codes and data matrix or barcodes. Lasers automate marking with pinpoint accuracy. Each part receives crisp codes or text in seconds without slowing the production line. Laser marks cannot be erased or smeared ensuring parts remain identifiable in harsh environments. Manufacturers in India widely use fiber lasers to permanently etch serial numbers on engine blocks motor nameplates and PCBs. Lasers integrate seamlessly with conveyors and vision systems allowing continuous automated operation.

Product Customization and Flexibility

Demand for personalized products is rising. Laser engravers allow on the fly customization without tooling changes. Manufacturers can engrave names logos designs or serial variations instantly. Small factories and MSMEs in India increasingly use tabletop lasers to expand offerings such as engraved leather goods customized gifts or branded metal components. Digital input allows instant job switching improving flexibility and profitability.

Batch Marking and Coding

Mass production requires uniform batch numbers expiry dates and manufacturing codes. Laser systems handle batch marking easily marking thousands of parts without tool wear. They can mark very small components and maintain consistency even at high volumes. In food pharma and packaging industries lasers produce compliant batch and date codes without adding cycle time.

Production Automation and Efficiency

Laser engravers integrate smoothly into automated workflows including robotic arms conveyor systems and inline marking stations. Once programmed lasers operate continuously with minimal human input. This reduces errors improves consistency and frees manpower. Conveyor enabled laser models allow hands off processing of long or bulky workpieces boosting throughput.

These capabilities deliver strong ROI. Lasers replace ink based or label based methods reduce rework and support Make in India manufacturing standards by meeting global quality requirements.

Applications in Indian Industry

Metal Nameplate and Tag Engraving

Factories engrave stainless steel nameplates for motors pumps generators and control panels ensuring durability and readability.

Automotive and Machinery Parts

Vehicle components such as engine blocks gearboxes and frames are permanently marked for traceability warranty and compliance.

Electronics and Semiconductors

PCBs connectors chips and enclosures are laser marked with serial numbers and data matrices that withstand heat and cleaning.

Jewelry Tools and Surgical Instruments

Fiber lasers engrave tiny fonts on rings tools and surgical instruments enabling branding identification and customization.

Leather Textiles and Paper

CO2 lasers engrave leather goods fabric patterns wood boxes and packaging materials for apparel gifts and FMCG industries.

Industrial Control and Automation

Laser engraved legends and serial numbers on machine parts improve maintenance identification and durability.

Laser engraving improves efficiency quality and standardization. Machine readable codes eliminate legibility issues and enable digital production workflows. Even MSMEs are adopting laser systems to modernize operations improve branding and enhance productivity.

Protomonts Laser Engraving Solutions

Protomont Technologies LLP offers a complete range of industrial laser engraving machines for professional and factory use.

xTool F2 Dual Laser Engraver

A portable dual laser system with 5W IR and 15W diode lasers capable of engraving over 300 materials. It features high speed engraving a 50MP camera and expandable workspace options.

xTool F2 Ultra Single and Dual

A heavy duty fiber laser platform with a 60W MOPA fiber laser delivering high speed metal engraving and color marking. Dual laser variants include an additional 40W diode head and optional conveyor systems for inline production.

xTool S1 40W Enclosed Diode Laser

A Class I enclosed desktop system suitable for cutting and engraving wood acrylic leather glass and coated metals with full safety enclosure.

xTool F1 and Portable Lasers

Lightweight portable diode engravers designed for customization prototyping and on site engraving tasks.

Snapmaker Artisan

An industrial grade three in one system combining 3D printing laser engraving and CNC machining in a large enclosed workspace ideal for R and D labs and design studios.

Figure: Protomont’s xTool S1 40W enclosed diode laser cutter, a desktop engraver designed for industrial use.

Beyond these Protomont offers other specialized laser systems: large CO₂ cutters for thick acrylic high power fiber lasers for heavy industrial marking, and accessories (rotary tables, ventilation) to tailor solutions. Every machine is backed by Protomont’s service network assuring Indian buyers of support and parts availability. In short Protomont’s portfolio covers any marking need from fine detail electronics labels to batch engraving on metal parts with trusted international brands.

Figure: Snapmaker Artisan 3-in-1 machine combines 3D printing, laser engraving and CNC providing versatile fabrication for small-scale production.

Maximizing Efficiency and ROI

Adopting laser engraving in manufacturing brings tangible returns:

- Reduced Waste and Downtime: Lasers eliminate consumables like inks or labels cutting operating costs. They also reduce errors (misaligned text, illegible prints) that cause rework. Keyence notes that lasers generate virtually no scrap from the marking process.

- Lower Maintenance: Modern lasers (especially fiber types) require little upkeep. Fiber lasers have sealed optics and no gas, and diode lasers have long lifetimes minimizing downtime. For example lens cleaning and occasional mirror alignment are the main tasks far less frequent than servicing an inkjet or stamp machine.

- Energy Efficiency: Laser processes are energy-concentrated and quick, often using less power overall than thermal or chemical marking systems. They also avoid chemical wastes, aligning with sustainability goals. The Keyence resource highlights lasers’ low environmental impact compared to etching chemicals.

- Streamlined Workflow: Many lasers include built-in cameras and software that guide operators. As xTool emphasizes, features like 50MP preview cameras and autofocus ensure marks are right on the first try. This cuts setup time and scrap conveyor and indexing options allow continuous operation with minimal manual handling.

- Future-Proofing: Finally, lasers support digital manufacturing trends. They can be easily reprogrammed via software updates and linked to IoT systems. As Industry 4.0 spreads lasers fit the vision of smart connected production.

For procurement professionals and factory owners these factors mean a laser engraver quickly pays for itself in higher productivity and quality. (Note: actual ROI will vary by use-case.) More importantly lasers keep companies competitive. In India’s market where foreign and domestic brands alike compete on quality the permanent precision of laser marking can be a differentiator.

Conclusion

Laser engraving machines have become an essential tool in modern manufacturing. Their precision speed versatility and reliability address critical needs from product traceability to mass customization. Industrial lasers mark everything from tiny electronic components to large metal panels often within fully automated lines. For Indian manufacturers and MSMEs adopting laser engraving means meeting global standards and customer expectations.

Protomont Technologies LLP stands ready to equip factories with the right laser solutions. Whether it’s an xTool F2 Ultra handling heavy duty metal engraving or a compact Snapmaker Artisan enabling rapid prototyping Protomont’s offerings combine professional-grade performance with local support. As technology advances lasers will only play a larger role in “Make in India” powering efficient high quality production.