In today’s rapidly evolving world, technology continues to revolutionize various industries, and the jewelry business is no exception. The advent of 3D printing has opened up a world of possibilities for jewelry designers and manufacturers, offering numerous advantages that can transform their businesses. From enhanced creativity to streamlined processes, 3D printing has the potential to redefine the way jewelry is produced and consumed.

In today’s rapidly evolving world, technology continues to revolutionize various industries, and the jewelry business is no exception. The advent of 3D printing has opened up a world of possibilities for jewelry designers and manufacturers, offering numerous advantages that can transform their businesses. From enhanced creativity to streamlined processes, 3D printing has the potential to redefine the way jewelry is produced and consumed.

Embracing creativity with jewelry that is created by 3D printing technology

Traditionally, jewelry making has been a labor-intensive craft that requires extensive technical expertise and time investment. However, with the introduction of 3D printing, jewelry designers can now explore new realms of creativity. The flexibility and freedom offered by 3D modeling enable designers to experiment with unique designs, intricate patterns, and captivating textures that were once challenging to achieve using traditional methods. The constraints of mold creation are eliminated, allowing designers to push the boundaries of what is possible in jewelry design.

Furthermore, 3D printing technology enables the production of larger jewelry pieces while maintaining intricate details. The build envelope of industrial-grade 3D printers allows for the creation of statement pieces with full detailing. Interlocking structures and complex geometries can be easily incorporated into the design, giving designers the opportunity to create truly distinctive and captivating jewelry pieces.

Personalization and Customer Engagement

One of the key advantages of 3D printed jewelry is the ability to provide a personalized experience for customers. With 3D printing, jewelry designers can easily customize designs to meet individual preferences and requirements. Whether it’s engraving a personal message or modifying existing designs, 3D printing enables designers to create one-of-a-kind pieces that resonate with their customers on a deeper level.

Moreover, the use of 3D rendering and modeling allows designers to engage with customers in real-time. Within a matter of hours, designers can present customers with 3D models of their desired jewelry, providing a tactile and interactive experience. This level of customer engagement not only enhances the overall buying experience but also ensures that the final piece meets the customer’s expectations.

Streamlining the Jewelry Production Process

Traditional jewelry production can be a time-consuming and costly process, often taking weeks or even months to complete. In contrast, 3D printing offers a streamlined production process that significantly reduces lead times. From prototyping to final production, the entire journey can be accomplished in a matter of days.

The iterative nature of 3D printing allows designers and manufacturers to make multiple changes and adjustments without incurring substantial costs. This flexibility ensures that the final piece meets the desired specifications and eliminates the need for costly rework. With 3D printing, jewelry businesses can optimize their production processes, minimize waste, and deliver high-quality pieces in a shorter timeframe.

Expanding Materials and Possibilities

Another advantage of 3D printing in the jewelry business is the wide range of materials available for use. From traditional metals like gold and silver to innovative materials like resin and plastics, 3D printing offers endless possibilities for material selection. Each material brings its unique properties and characteristics, allowing designers to explore different aesthetics and functionalities.

For those seeking colorful and vibrant jewelry, resin 3D printing offers a smooth surface finish that can be painted in various hues. Plastic materials, such as those used in FDM, SLS, and MJF 3D printing, provide lightweight options without compromising durability. Metal 3D printing, on the other hand, opens up a whole new realm of possibilities, enabling the production of high-quality metal jewelry pieces in materials like brass, bronze, and steel.

Lightweight and Comfortable Jewelry

Comfort is a crucial factor when it comes to jewelry, especially for larger pieces like earrings or necklaces. 3D printing offers the advantage of creating lightweight jewelry that is comfortable to wear without sacrificing quality or style. Through the use of lattice structures, designers can reduce the weight of the jewelry while maintaining its structural integrity. Additionally, hollowing techniques can be employed to further reduce weight, particularly for larger ornaments or decorative pieces.

Different 3D printing technologies cater to specific weight requirements. FDM, SLS, and MJF 3D printing excel in producing lightweight plastic jewelry, while metal 3D printing, such as SLM, offers the ideal solution for lightweight metal jewelry, the DLP 3D Printers are also a effective all round choice for 3D jewelry printing The ability to create lightweight and comfortable jewelry opens up new possibilities for designers and provides customers with pieces they can enjoy wearing for extended periods.

Easy Mass Production and Cost Efficiency

While 3D printing is known for its customization capabilities, it also offers advantages in mass production. The technology enables easy replication of designs, making it a cost-effective solution for producing multiple pieces of jewelry. In the traditional manufacturing process, creating molds for mass production can be expensive and time-consuming. However, 3D printing allows designers to create jewelry samples quickly for visual and mechanical identification before moving into larger-scale production methods, such as injection molding.

By utilizing 3D printed jewelry samples, designers can identify any design flaws or improvements before investing in expensive molds. This reduces the risk of errors during mass production and ensures a smoother and more cost-efficient manufacturing process. While 3D printing may not always be the final production method for jewelry businesses, it serves as a valuable tool in the overall production workflow.

Versatility and Flexibility in Design

3D printing offers a wealth of possibilities for jewelry designers, ranging from prototyping to mass production. Designers can create end-use jewelry directly through 3D printing or use 3D printed jewelry as master molds for traditional mold making or casting processes. This versatility allows designers to choose the most suitable approach based on their specific needs and the desired outcome.

The size of the jewelry is not limited by 3D printing technology, enabling designers to create both small and large pieces with ease. Additionally, the ability to print joint jewelry pieces offers even more design possibilities, allowing for the creation of intricate and unique jewelry designs. Material flexibility is another highlight of 3D printing, as designers can choose from a wide range of materials to achieve their desired aesthetics and functionality.

Realizing High-Quality Details

3D printing technology has pushed the boundaries of jewelry craftsmanship, enabling designers to achieve high levels of detail that may not be achievable through traditional handcrafting methods. The precision and accuracy of 3D printing ensure that every intricate detail in the design is faithfully reproduced, resulting in stunning pieces of wearable art.

The ability to capture and reproduce intricate details has become a hallmark of 3D printed jewelry, elevating the overall quality and craftsmanship of the pieces. From delicate engravings to intricate filigree designs, 3D printing allows designers to showcase their creativity and attention to detail in ways that were once unimaginable.

Real-Life Examples of 3D Printed Jewelry

To showcase the possibilities of 3D printed jewelry, let’s explore two real-life examples of jewelry businesses that have embraced this technology:

- Jorge Rojas: Jorge Rojas creates mesmerizing jewelry pieces that he refers to as “containers of emotion.” His jewelry collection showcases organic forms, shapes, and elements, all made possible through 3D printing. This technology allows him to bring his unique designs to life with precision and intricacy.

- Ola Shekhtman: Ola Shekhtman draws inspiration from architecture and her love of travel to create her Cityscape Ring Collection. By leveraging 3D printing, she can capture the essence of various cities and transform them into wearable art. The level of detail and accuracy achieved through 3D printing enhances the overall aesthetic appeal of her jewelry.

These examples demonstrate the limitless possibilities that 3D printing brings to the world of jewelry design. From abstract forms to architectural inspirations, designers can push the boundaries of their creativity and create truly exceptional pieces.

Getting Started with 3D Printed Jewelry

If you’re ready to embark on your journey into the world of 3D printed jewelry, here are some steps to consider:

- Find Inspiration: Explore the work of other jewelry brands and designers who have embraced 3D printing. Gain inspiration from their designs, market positioning, and customer profiles. Use their work as a starting point to develop your unique style and vision.

- Learn 3D Modeling: Familiarize yourself with 3D modeling software and apps that enable you to create intricate and detailed jewelry designs. Popular software options include Autodesk, Onshape, Thinkercad, Blender, ZBrush, and Vectary. Mastering these tools will empower you to bring your jewelry designs to life digitally.

- Choose the Right 3D Printing Technology: Understand the different 3D printing technologies available and select the one that best suits your specific design requirements. Consider factors such as material compatibility, level of detail, and production volume. Technologies like FDM, SLS, MJF, and metal 3D printing offer a wide array of options for creating your jewelry pieces.

- Prototype and Refine: Utilize the benefits of rapid prototyping to create multiple iterations of your designs. This allows you to test and refine your jewelry pieces, ensuring they meet your desired specifications and aesthetic vision. Make use of 3D rendering and modeling to showcase realistic renders to potential customers for feedback and customization.

- Production and Manufacturing: Once your designs are finalized, choose a reliable 3D printing service provider or invest in your own 3D printer to produce your jewelry pieces. Consider factors such as cost, quality, and turnaround time when selecting a production method. Collaborating with a trusted 3D printing service provider can simplify the production process and ensure high-quality results.

- Marketing and Distribution: Develop a comprehensive marketing strategy to promote your 3D printed jewelry brand. Leverage social media platforms, online marketplaces, and traditional marketing channels to reach your target audience. Showcase the unique aspects of your 3D printed jewelry, such as customization options, intricate details, and high-quality craftsmanship, to attract potential customers.

By following these steps, you can embark on an exciting journey into the world of 3D printed jewelry and unleash your creativity in ways that were once unimaginable.

The Future of Jewelry Making

As technology continues to advance, the future of jewelry making looks incredibly promising. 3D printing will likely play an increasingly significant role in transforming the industry, offering new possibilities for designers, manufacturers, and consumers alike. The ability to create personalized, high-quality, and intricate jewelry pieces with ease will redefine the way we perceive and appreciate wearable art.

Embrace the power of 3D printing in the jewelry business and embark on a journey that combines innovation, creativity, and craftsmanship. With this technology at your fingertips, you have the opportunity to create jewelry pieces that truly captivate and inspire. The future of jewelry making has arrived, and it’s time to embrace the limitless possibilities that 3D printing brings.

Best 3D Printer For Jewelry

Elegoo Mars 5 Ultra 9K LCD 3D Printer

₹31,999.00 Incl. of all taxes- 150mm/h speed for fast printing.

- 7-inch 9K Mono LCD resolution with 18μm precision.

- 92% light uniformity for consistency.

- Self-check and auto-leveling simplify setup.

- AI camera for real-time monitoring.

- Mechanical sensor prevents damage.

- Time-lapse capture for easy sharing.

- Overheat protection at 80°C.

- Power-loss resume functionality.

- Quick-release plate and dual spout tank.

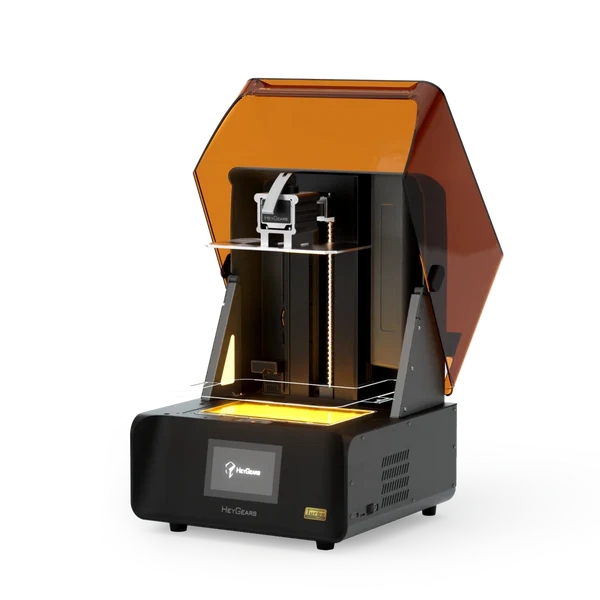

HeyGears UltraCraft Reflex RS Turbo 3D Printer – 8K Resin Printer

₹114,999.00 Incl. of all taxesBuy the HeyGears UltraCraft Reflex RS Turbo 3D Printer – 8K Amber LCD, ±15 µm precision, auto leveling, resin refill, and 4.5 s/layer printing. Perfect for hobbyists & professionals in India.

Order Now – Experience the future of high-precision resin 3D printing.

Request a Demo – See the HeyGears UltraCraft Reflex RS Turbo 3D Printer in action.

Contact Us – For local service, spare parts, and technical support.

ELEGOO Saturn 3 Ultra 12K 3D Printer : Precision, Speed, and Efficiency

₹42,999.00 Incl. of all taxesELEGOO Saturn 3 Ultra 12K 3D Printer

Experience the ultimate printing precision and quality with the ELEGOO Saturn 3 Ultra 12K 3D Printer. This advanced 3D printer features a 10-inch 12K mono LCD with an impressive resolution of 11520×5120, delivering exceptional details and sharp edges in your prints. With an XY resolution of 19×24 microns, you can create highly precise and accurate models.

ELEGOO JUPITER 12.8 6K MONO MSLA 3D PRINTER

₹90,110.00 Incl. of all taxesExclusively available in India by Protomont Technologies.

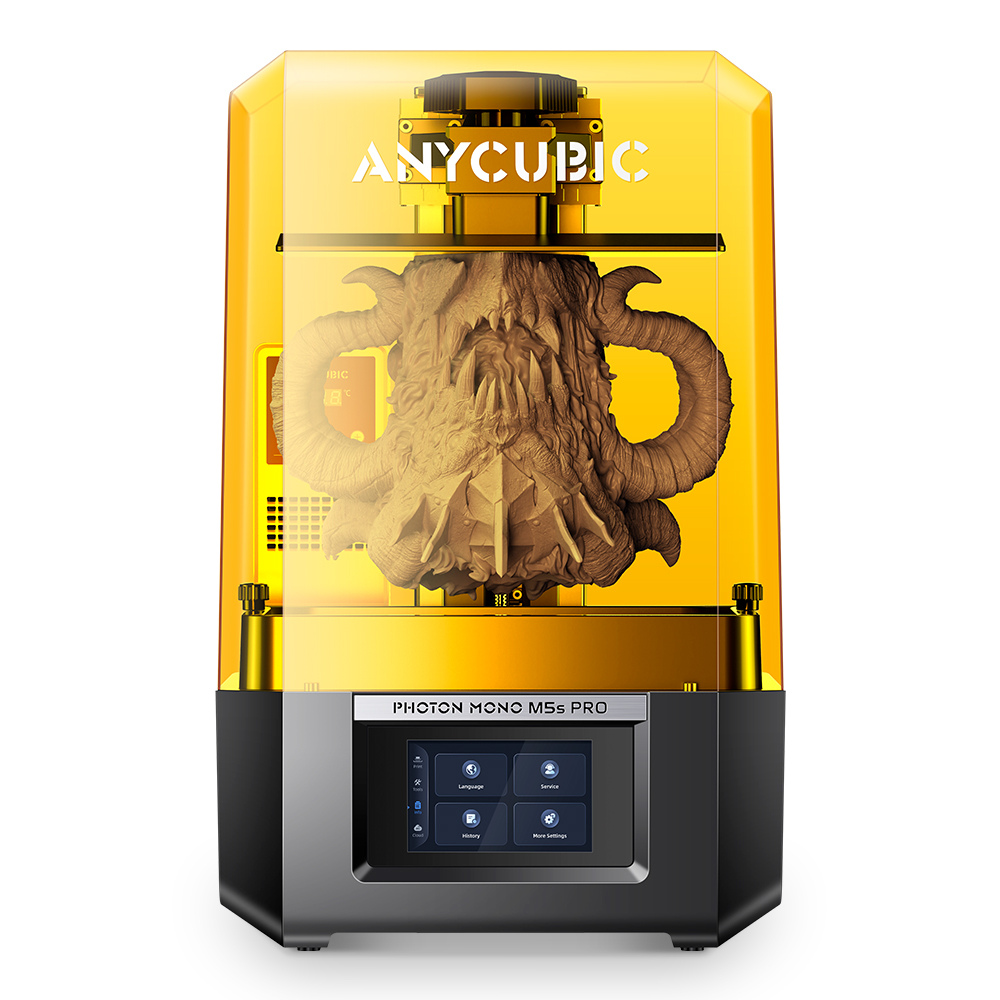

Anycubic Photon Mono 4 Ultra LCD 3D Printer

₹31,999.00 Incl. of all taxesHigh-Precision 10K Resin 3D Printer for Professionals, Designers, and Enthusiasts in India Now Available at Protomont Technologies

Anycubic Photon Mono 4 LCD 3D Printer

₹20,999.00 Incl. of all taxes- 10K resolution for ultra-high detail.

- 7″ HD screen for clear visuals.

- LighTurbo light for faster, even prints.

- 2.2L volume for large models.

- 17μm precision for accuracy.

- 17μm pixels for fine detail.

- Laser-engraved platform for strong adhesion.

- 4-point leveling for easy setup.

- Resume function after power loss.

- Optional air purifier for cleaner air.

- Supports PhotonWorkshop