Additive manufacturing has affected many industries, but few stand to benefit as much as the dental fields, especially dentistry. Thanks to the advanced 3D printers for dental rapid prototyping.

Dentistry as field and dental laboratories are today optimizing the usage of 3D printers for dental rapid prototyping or using 3D Printer for Dental Aligners

This is not only making life easier for dental professionals but also yielding desirable results and tangible benefits for patients: tailored dental solutions are now more effective and affordable than ever, and there are fewer chances of error and more precision in the final product.

3D printer for dental aligner:

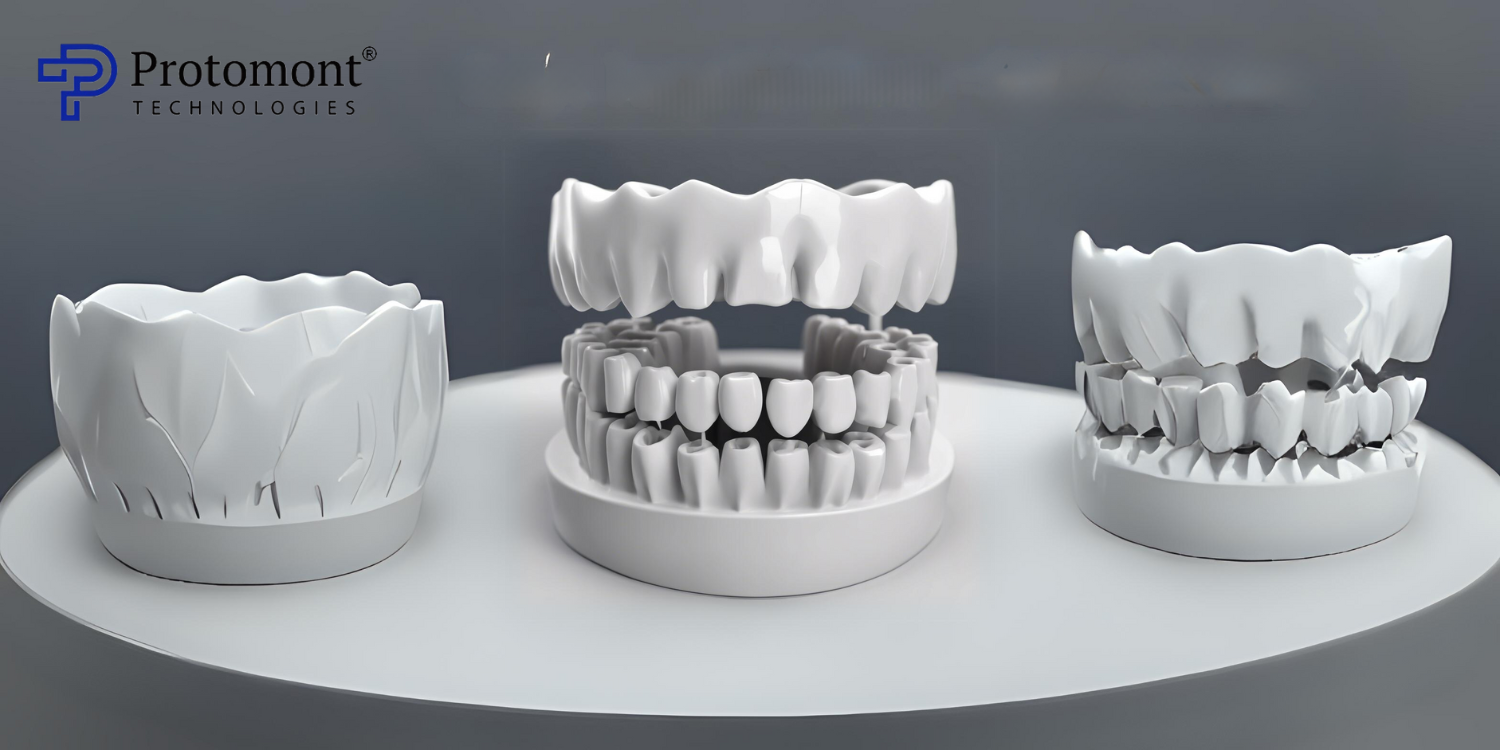

Clear aligners couldn’t have been possible without the intervention of 3D printers for dental aligners manufacturing process is an intense combination of multiple digital workflows. An orthodontist or dentist first captures an impression of a patient’s dentition with a 3D intraoral scanner or takes a traditional impression for the lab to scan.

Using the digital model, the incremental stages between the current and desired tooth positions can be planned. Each stage is then 3D printed, and the aligners are thermoformed over these molds

3D printing was initially used in dental applications specifically for molds. 3D printed products needed some important post-processing steps and supported a limited number of materials. But today, there is numerous combination of next-generation hardware, software, and materials that are allowing direct printing of products with improved materials and finish that require minimal to no post-processing.

Dentists, Orthodontists, and several dental labs are benefitting from the advantages of 3D printing in dentistry.

Perfect fit for the patients:

Oral devices require customization that fits the patients accurately. 3D printers can create complicated structures and allow for greater geometric difficulty without sacrificing production time.

Usage of 3D printers for dental rapid prototyping:

The prototyping process is sped up by 3D printing, which can produce parts within hours. This allows for each stage to complete quicker. Compared to machining prototypes, 3D printing is low-cost and quicker at creating parts as the part can be completed in hours, allowing for each design alteration to be completed at a much more efficient rate.

Lesser wastage

The production of parts only requires the materials needed for the part itself, Not only does the process save on resources but it also reduces the cost of the materials being used.

Easy to use

3D printers are becoming more and more manageable with more local service providers offering outsourcing services for manufacturing work. This saves time and doesn’t require exclusive transport costs compared to more old-style manufacturing processes.

Cost-effective

As a one-step manufacturing process, 3D printing saves time and therefore costs related to using diverse machines for manufacture. 3D printers can also be set up and left to get on with the job, meaning that there is no need for operators to be present the entire time.

Protomont Technology aims to craft your vision with creativity, empowering ideas & unleashing imaginations. We endeavor to be your trusted printing partner with all kinds of 3D printers, 3D printers for dental rapid prototyping, 3D printers for Dental Aligners, spare parts, 3D filaments, and 3D scanners.

click here if you are interested in buying a dental 3D printer.