Metal 3D printing, or metal additive manufacturing, has revolutionized the manufacturing industry, enabling companies to create intricate, durable metal parts that were once limited to prototype development. The demand for metal 3D printers has surged in India, fueled by their ability to produce complex geometries, reduce waste, and support industries such as aerospace, medical, and automotive. This article explores the factors influencing the metal 3D printer price in India and highlights the technology and applications shaping this transformative manufacturing method.

What is metal 3D printing?

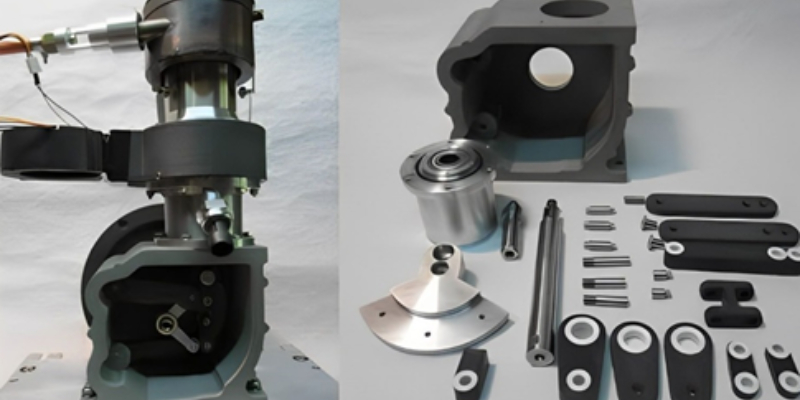

Metal 3D printing involves building metal objects layer by layer from powdered metal, which is fused by lasers or electron beams. Technologies like Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) drive this process, creating components that match, or exceed, the precision of traditional manufacturing methods. These methods provide design flexibility, enabling the production of complex shapes that are often impossible to achieve with conventional techniques.

Key benefits of metal 3D printing

- Design Complexity and Flexibility

Metal 3D printers allow manufacturers to create complex, multi-functional parts in one piece, reducing the need for assembly and decreasing potential failure points. This is especially valuable in aerospace and automotive sectors. - Reduced Material Waste

As an additive manufacturing process, metal 3D printing uses only the material required, minimizing waste significantly compared to traditional subtractive methods like CNC machining. - Customization and Rapid Prototyping

Metal 3D printing supports fast design iteration, making it ideal for industries requiring custom or prototype parts, such as medical implants and specialized aerospace components. - Lightweight and Durable Structures

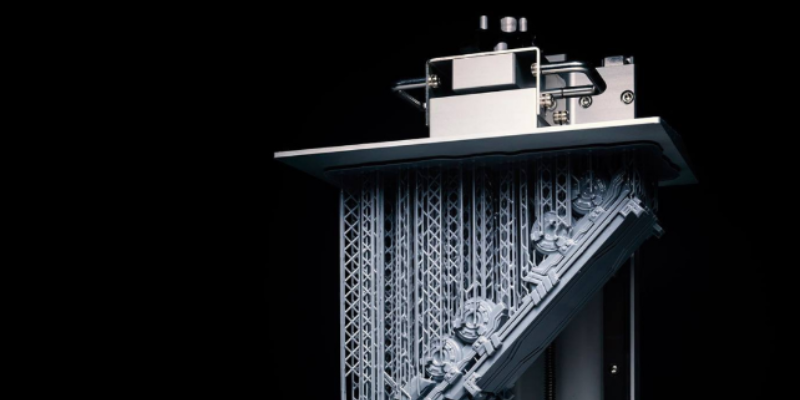

The technology’s ability to produce lightweight yet strong structures through lattice designs and hollow forms enhances performance in weight-sensitive industries. - Cost-Effectiveness for Low to Medium Production

Metal 3D printing is cost-effective for short production runs and custom parts, bridging the gap between prototyping and large-scale production.

Metal 3D printing materials

Metal 3D printers support a range of materials suited for various applications:

- Steel: Widely used for its versatility and durability.

- Titanium: Lightweight and highly resistant to heat, ideal for aerospace applications.

- Aluminum: Preferred in automotive and aerospace for its light weight.

- Nickel Alloys: Known for high-temperature tolerance, used in demanding aerospace applications.

- Precious Metals: Gold and silver find use in jewelry and specialized electronics.

Metal 3D printing technologies

Protomont Technologies, a leader in SLM 3D printing in India, offers cutting-edge solutions such as SLM and DMLS technologies. High-performance models like the BLT-S800 and MELT SLM M300 cater to a wide array of applications, from aerospace to medical, enabling Indian businesses to stay competitive globally.

Factors influencing metal 3D printer prices in India

The metal 3D printer price in India varies significantly based on several key factors:

- Printer Type and Technology

Different technologies, such as SLM and DMLS, come with varying levels of capability and cost. Higher-end models with advanced features generally command a higher price. - Build Volume and Precision

Larger printers with high-resolution capabilities tend to be more expensive. Small industries or sectors focusing on intricate designs may opt for compact, high-precision models. - Material Compatibility

Metal 3D printers supporting diverse materials, such as titanium, aluminum, and steel alloys, often come at a premium due to their versatility. - Operating and Maintenance Costs

The long-term cost includes expenses for regular maintenance, calibration, and material use, which are essential considerations for businesses assessing ROI.

Average metal 3D printer prices in India

In India, metal 3D printer prices typically start from around ₹20–30 lakh for entry-level models, while premium models with extensive capabilities can exceed ₹1 crore. Companies in India can now choose from a range of models that align with their specific needs and budgets, making metal additive manufacturing an attainable goal for more industries.

Why Choose Protomont Technologies for Metal 3D Printing?

Protomont Technologies is a pioneer in India, offering a comprehensive range of SLM metal 3D printers, such as the BLT-S800, MELT SLM M140C, ZRapid iSLM420, and MELT SLM M180. With competitive pricing, exceptional customer support, and cutting-edge technology, Protomont helps businesses integrate 3D printing into their operations seamlessly. Their expertise in SLM 3D printing ensures high-quality output, reduced lead times, and enhanced production efficiency for Indian industries.

As metal 3D printing continues to evolve, it promises endless possibilities for Indian industries looking to stay at the forefront of manufacturing. With factors like printer technology, build size, and material compatibility influencing the metal 3D printer price in India, companies have a range of options tailored to their unique requirements. Protomont Technologies remains committed to offering reliable and innovative 3D printing solutions, helping Indian businesses unlock the potential of this transformative technology.