In today’s digital age, 3D scanners are pivotal tools across various industries, helping users capture the shape and appearance of physical objects to produce digital models that can be analyzed, modified, and reproduced. As you consider purchasing a 3D scanner,

Understand the factors that influence 3D scanner prices

Accuracy & Precision

A primary driver of 3D scanner pricing is the accuracy it provides. High-precision scanners yield detailed, reliable models essential for fields like engineering, architecture, and medical imaging. This level of precision, however, comes at a higher cost. Investing in a high-quality scanner ensures minimized errors and reduces the need for re-scanning, offering value by delivering reliable results that save time and resources in the long run.

Scanner Complexity & Features

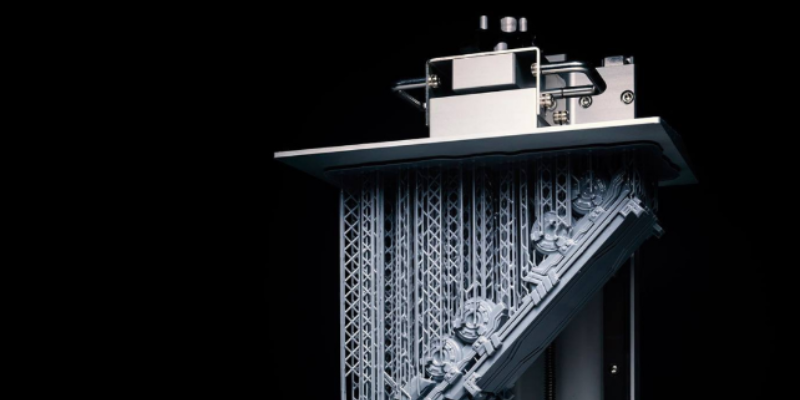

The internal technology and design of a 3D scanner affect its cost significantly. Advanced scanners often come equipped with multi-sensor technology, high-resolution imaging, and fast scanning capabilities. For instance, the ELEGOO REVOPOINT POP RANGE 3D Scanner offered by Protomont Technologies is designed for versatile scanning applications. Powerful software enhances ease of use and compatibility with various systems, often reflected in the price. It's essential to weigh these complex features against your needs to ensure you’re not overpaying for capabilities you may not require.

Research & Development (R&D) Costs

Manufacturers invest extensively in R&D to develop innovative 3D scanners, and these expenses are generally factored into the final cost. Opting for scanners from companies that prioritize R&D, like ELEGOO’s REVOPOINT MINI 3D Scanner, means you're choosing a product that will likely offer regular updates, ongoing support, and better long-term value. This innovation in technology also guarantees your scanner stays relevant, reducing the need for frequent replacements.

Market demand & competitive dynamics

The 3D scanner price can fluctuate based on market demand. In competitive markets, prices may be more accessible as brands compete for customer attention. However, if specific features are in high demand, costs may rise. Staying informed on market trends and comparing features can help you balance cost and functionality, securing the best value for your application.

Applications of 3D scanners

3D scanners are transforming industries from manufacturing to healthcare with a range of applications. Here’s a glimpse of their versatility:

- Prototyping: Scanners aid in the prototyping phase of product development by creating digital models that can be refined before production, saving both time and materials.

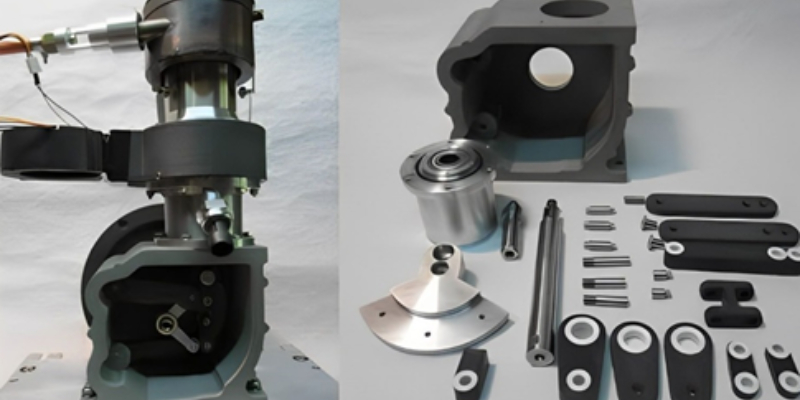

- Reverse Engineering: Engineers can capture existing designs through scanning to create precise CAD files, aiding in the replication or enhancement of parts.

- Quality Control: By verifying product dimensions and surface quality, scanners uphold quality standards, particularly in manufacturing.

- Medical Applications: In healthcare, scanners enable custom healthcare products, such as prosthetics, tailored to individual patient needs for improved comfort and functionality.

Object geometry & size

The geometry and size of objects to be scanned also play a role in determining the right 3D scanner and, by extension, the cost. Scanners suited for large or complex objects are often pricier as they require specialized features or multiple scanning sessions. For example, handheld scanners are ideal for larger objects, while desktop scanners are better suited for smaller, intricate items. Choosing the right scanner based on object size can help avoid unnecessary spending.

Environmental Conditions

Environmental adaptability influences 3D scanner costs. Models that operate effectively in diverse or outdoor environments usually come with a higher price tag, as they’re equipped with technology to handle challenging conditions like poor lighting or fluctuating temperatures. If your projects require scanning in unpredictable settings, investing in a durable, adaptable scanner is essential for consistent results.

Expected Quality of the Final Output

The level of detail required for your projects is another key factor. High-detail models are essential for medical imaging or architectural design applications, which need advanced sensors and software. Before investing, assess the quality level you need and invest accordingly.

How 3D Scanners Are Shaping Design & Manufacturing

3D scanners and 3D printers are revolutionizing design and manufacturing by streamlining workflows and enhancing accuracy. Manufacturers leverage 3D scanners to uphold quality control by creating digital models and comparing them to original CAD files, ensuring products meet specifications. In reverse engineering, scanners enable the swift digitization of physical structures, facilitating replacement parts and product improvements. For instance, Protomont Technologies offers a wide range of 3D scanners and printers, guiding engineers, designers, architects, and other professionals to bring their ideas to life.

3D Printing & Prototyping: With 3D printing, businesses can create prototypes quickly and iteratively, reducing development time and costs by enabling rapid visualization and testing of ideas.

Choosing the Right 3D Scanner

Evaluating your specific needs and budget is crucial when selecting a 3D scanner. Entry-level models may suit hobbyists or small businesses, while industrial-grade scanners are designed for high-precision applications in engineering, healthcare & manufacturing.

Protomont Technologies in Mumbai is a trusted distributor of ELEGOO products, providing an array of 3d scanners, 3d printers, filaments, and spare parts to support professionals across industries. With offerings like the REVOPOINT RANGE 3d Scanner, they are helping companies enhance design and manufacturing workflows with accuracy and efficiency.