Understanding SLM metal 3d printing: Revolutionizing manufacturing with protomont technologies

In the fast-paced world of manufacturing, metal 3D printers, especially those using SLM (Selective Laser Melting) technology, are transforming how industries approach production. While traditional methods like casting and machining have long dominated the field, SLM technology offers a new level of precision, customizability, and efficiency. Protomont Technologies, a leader in industrial additive manufacturing, provides advanced solutions for businesses across sectors. With state-of-the-art SLM 3D printers like the BLT-S800, BLT-S1000, and MELT SLM M180, Protomont is committed to redefining manufacturing standards.

What is SLM Metal 3D Printer printing?

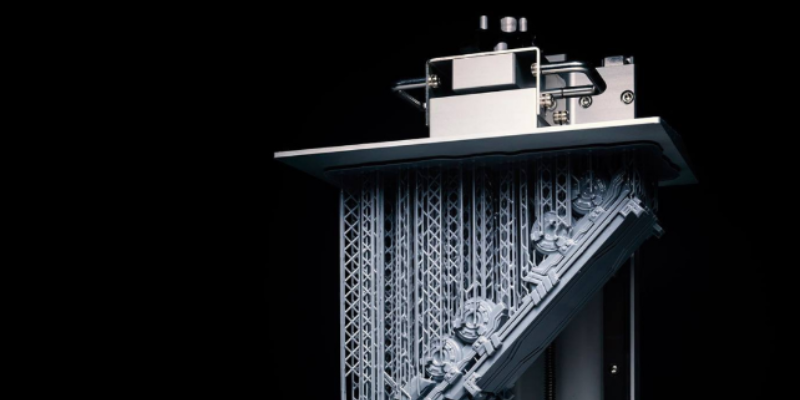

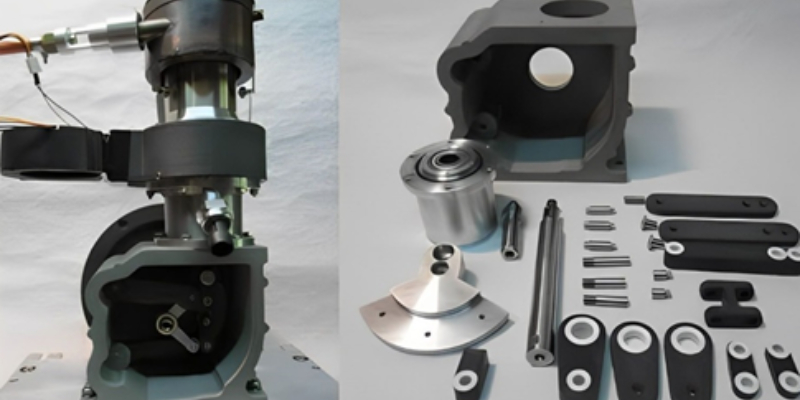

Selective Laser Melting (SLM) is an additive manufacturing process that utilizes a high-powered laser to fuse fine metal powder layer by layer, producing solid metal parts with intricate geometries. This powder bed fusion technology allows for the production of complex structures that are challenging or even impossible to achieve with traditional manufacturing.

Protomont's BLT-S800, BLT-S1000, and MELT SLM M180 feature cutting-edge laser technology and robust build volumes, making them ideal for industries such as automotive, healthcare, and engineering, where precision and quality are paramount.

Why choose Protomont's metal 3d printer?

Complexity Without Compromise

Protomont’s SLM 3D printers can produce intricate parts in a single build, significantly reducing assembly times. This capability is vital for industries that require lightweight yet durable structures, such as aerospace.Reduced Material Waste

SLM is an additive process, using only the material necessary. Protomont’s SLM solutions offer sustainable manufacturing by minimizing waste, a significant advantage over subtractive methods.Customization and Rapid Prototyping

Protomont’s BLT-S800 and BLT-S1000 enable rapid production of customized parts. Whether for healthcare implants or high-performance automotive components, our SLM printers accelerate design iterations and time-to-market.On-Demand Production and Cost Efficiency

Digital design files mean that parts can be produced on demand, streamlining supply chain management. Protomont’s MELT SLM M180 is optimized for small-to-medium production runs, making it cost-effective for businesses of various scales.

Materials for SLM 3d printing

Protomont’s metal 3D printer are compatible with a wide range of materials, ensuring versatility across applications:

- Stainless Steel for corrosion-resistant components.

- Titanium Alloys for high strength-to-weight applications, particularly in aerospace.

- Aluminum for lightweight, efficient parts in automotive.

- Nickel Alloys for high-temperature resilience, perfect for aerospace engines.

Key industries benefiting from metal 3D Printer

Aerospace

Protomont’s SLM 3D printers are essential in producing lightweight, complex components, such as turbine blades and engine parts, to boost fuel efficiency.Healthcare

The BLT-S800 and MELT SLM M180 allow for personalized medical implants, advancing patient-specific treatment.Automotive

Protomont’s SLM printers are ideal for creating high-performance, custom automotive parts that enhance vehicle efficiency and performance.

Challenges and the future of SLM

While SLM technology presents a significant upfront investment, advancements in material science and hybrid manufacturing techniques continue to improve the cost-effectiveness and scalability of SLM. Protomont remains at the forefront, providing top-tier metal 3D printer and support to help industries leverage this transformative technology.

Protomont Technologies’ BLT-S800, BLT-S1000, and MELT SLM M180 represent the cutting edge of metal additive manufacturing. For more information on metal 3D printer pricing in India and to explore our full suite of industrial solutions, connect with Protomont Technologies your partner in the future of manufacturing