A dental 3D printer is a specialized type of additive manufacturing technology used to produce dental parts and appliances. This includes items such as dentures, crowns, implants, and surgical guides. Dental 3D printers utilize various printing technologies, such as stereolithography (SLA) and digital-light processing (DLP), to create highly detailed and precise dental replicas based on digital models. These technologies enable the production of custom-made dental prosthetics and models that perfectly fit each patient’s unique oral anatomy, ultimately leading to better outcomes for patients.

A dental 3D printer is a specialized type of additive manufacturing technology used to produce dental parts and appliances. This includes items such as dentures, crowns, implants, and surgical guides. Dental 3D printers utilize various printing technologies, such as stereolithography (SLA) and digital-light processing (DLP), to create highly detailed and precise dental replicas based on digital models. These technologies enable the production of custom-made dental prosthetics and models that perfectly fit each patient’s unique oral anatomy, ultimately leading to better outcomes for patients.

Applications in dental 3D printer

How 3D Printing Helps in Dentistry?

Prosthetics and Implants: Dental 3D printers are at the forefront of digital dentistry, excelling in the production of custom prosthetics such as crowns, bridges, dentures, and dental implants. This additive manufacturing technology allows for the creation of patient-specific devices that perfectly align with the patient’s unique oral anatomy, resulting in superior aesthetic and functional outcomes.

Orthodontics: 3D printing in dentistry has revolutionized the field of orthodontics by enabling the meticulous crafting of orthodontic aligners, retainers, and brackets. These customized devices are tailored to fit each patient’s teeth, enhancing both the comfort and precision of orthodontic treatments. This advancement in dental technology has made orthodontic care more effective and patient-friendly.

Surgical Guides: The role of 3D printing in dentistry extends to the creation of surgical guides that ensure precise implant placement during dental implant surgeries. These guides facilitate accurate drilling and positioning, significantly improving the success rates of these procedures. Additionally, dental 3D printers are used to produce custom scaffolds for bone regeneration and reconstruction, supporting more complex surgeries and advancing precision dentistry.

Educational Models: Educational models produced through additive manufacturing are invaluable in dental education. These highly detailed 3D printed models allow students and practitioners to practice and refine their skills in a realistic setting. They also play a crucial role in patient education, helping individuals better understand proposed treatments and procedures.

Customization and Precision: The ability of dental CAD/CAM and 3D printing in dentistry to create components that are customized to each patient’s specific needs ensures that every dental solution is perfectly suited to the individual. This precision dentistry approach leads to improved outcomes and higher patient satisfaction.

Rapid Prototyping and Tooling: Dental 3D printers are also instrumental in the rapid prototyping of new dental devices, instruments, and tools. This capability enables the quick development and testing of innovative solutions, thereby accelerating advancements in dental technology and expanding dental applications.

Technologies Used in Dental 3D Printing

Dental 3D printers have significantly advanced modern dentistry by enhancing precision, speed, and customization. These technological improvements ensure that dental professionals can deliver high-quality results with greater efficiency.

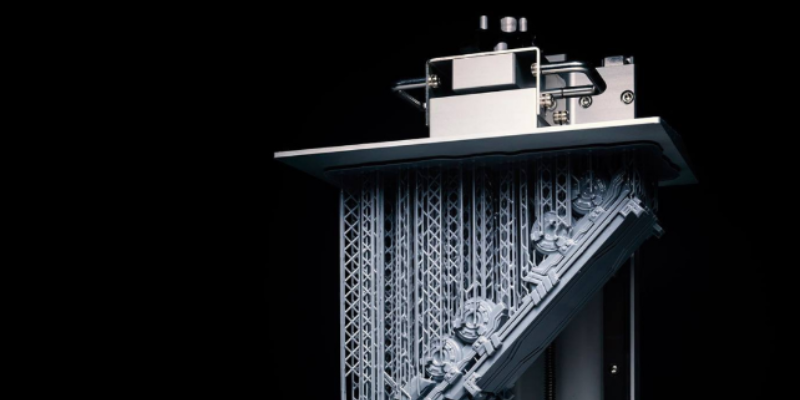

Higher Resolution Printers

The latest dental 3D printers are equipped with high-resolution capabilities, allowing for the creation of dental components with remarkable detail and accuracy. This precision ensures that dental prosthetics and appliances fit perfectly, which enhances patient comfort and improves treatment outcomes. High-resolution printing also enables better customization, allowing each solution to be tailored to the specific needs of the patient.

Faster Printing Speeds

Modern dental 3D printers have drastically reduced production times, enabling the creation of dental parts in just a few hours instead of weeks. This enhancement boosts productivity in dental practices, allowing for quicker turnaround times for restorations and appliances. As a result, patients experience shorter wait times and improved satisfaction with their dental care.

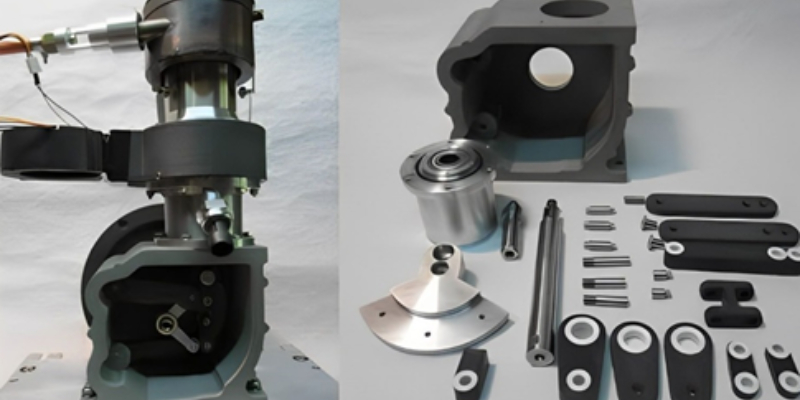

Integration with Digital Scanning

The integration of dental 3D printers with digital intraoral scanning has created a seamless workflow from diagnosis to treatment planning and production. Digital scanning captures detailed images of a patient’s mouth, which are then transformed into precise 3D models. These models are used to design and manufacture custom dental appliances, ensuring accuracy and effectiveness in dental procedures.

Protomont Technologies offers a range of dental 3D printers that incorporate these advanced technologies, including models from the ELEGOO and ANYCUBIC series. These 3D printers are available for purchase on platforms such as Amazon, Indiamart, Justdial, and the company’s official website. By exploring these platforms, you can review the features, specifications, and pricing of each printer to select the best option for your needs.

Materials Used in Dental 3D Printing

Dental 3D printing is a revolutionary technology that allows for the fast and precise production of various dental products, customized to meet individual patient needs. The materials used in this process are vital to its effectiveness, each offering unique benefits for specific dental applications. Key materials in dental 3D printing include polymers, ceramics, metals, and specialized resins, such as those provided by Protomont Technologies and Filamont.

Dental 3D printing is a revolutionary technology that allows for the fast and precise production of various dental products, customized to meet individual patient needs. The materials used in this process are vital to its effectiveness, each offering unique benefits for specific dental applications. Key materials in dental 3D printing include polymers, ceramics, metals, and specialized resins, such as those provided by Protomont Technologies and Filamont.

Polymers

Polymers are a popular choice in dental 3D printing due to their versatility. They are essential for creating items like surgical guides, custom trays, and temporary restorations. Common polymers include:

- Polycaprolactone (PCL): Known for its flexibility and biodegradability, it’s used in applications where the material needs to break down over time.

- Polymethyl Methacrylate (PMMA): This durable, clear material is ideal for temporary crowns and dental models.

- Polylactic Acid (PLA): Recognized for its ease of printing and environmental friendliness, PLA is often used for detailed dental models.

These polymers are crucial in helping dental 3D printers produce highly accurate and customized dental components.

Ceramics

Ceramics are valued in dental 3D printing for their strength and natural tooth-like appearance. They are commonly used for fabricating crowns, bridges, and veneers. These materials provide durability and an aesthetic that closely resembles real teeth, making them ideal for permanent dental restorations.

Metals

Metals, such as titanium and cobalt-chromium alloys, are essential in dental 3D printing for applications requiring exceptional strength. These metals are often used in dental implants and dentures that must endure significant force. Titanium is especially prized for its biocompatibility, integrating well with bone tissue.

Specialized Resins

Protomont Technologies and Filamont offer specialized resins designed specifically for dental 3D printing. These special series resins are crucial for creating detailed, biocompatible dental prosthetics and models. Available at affordable prices, these resins can be found on their websites and online platforms. These resins are formulated to be safe for in-mouth use and meet stringent health standards, ensuring high-quality results in dental applications.

Benefits of Dental 3D Printing

Utilizing 3D printing in dentistry offers numerous advantages, including increased speed in producing dental appliances, reduced costs through in-house production, and the ability to create highly customized products tailored to individual patient needs. Furthermore, 3D printing enhances the overall efficiency of dental workflows by streamlining the production process from digital model creation to final appliance delivery13.

Customization

The ability to produce highly customized dental prosthetics is one of the most significant advantages of 3D printing. Each dental appliance can be tailored to fit the unique anatomy of the patient, ensuring maximum comfort and effectiveness. Customization also extends to aesthetics, as 3D printing allows for the creation of dental components that match the color and texture of the patient’s natural teeth.

Precision and Accuracy

3D printing technology offers unparalleled precision and accuracy. Dental models and prosthetics produced using 3D printing fit better and require fewer adjustments compared to those made using traditional methods. This high level of accuracy ensures that treatments are more effective and less invasive, leading to better patient outcomes.

Speed and Efficiency

The speed at which dental prosthetics can be produced using 3D printing is a game-changer for the industry. Reduced turnaround times mean that patients spend less time waiting for their dental solutions, and dental practices can serve more patients efficiently. This speed also translates to lower costs, as less time and labor are required to produce each dental component.

Cost-effectiveness

3D printing is not only fast but also cost-effective. The technology minimizes material waste, as only the necessary amount of material is used to create each dental component. Additionally, the automation of the printing process reduces the need for manual labor, further lowering costs. Over time, the efficiency and precision of 3D printing can lead to significant savings for dental practices.