3D printers have revolutionized industries by transforming the way we approach design and manufacturing. From 3D printed toys to 3D printed home decor, the uses of 3D printers are extensive and diverse. Whether it's architectural models, dental crowns, or action figures, 3D printing enables the creation of intricate, customized designs quickly and efficiently.

Architects and engineers rely on 3D printers to create precise, scaled-down models of buildings and infrastructure, saving both time and resources. The ability to 3D print complex geometries, often using advanced technologies like SLA, DLP, FDM, and SLM, has also found applications in fields like healthcare, education, and fashion. For example, dental clinics use 3D printed crowns and bridges made from specialized dental resins to provide better patient care.

At Protomont Technologies, we offer a variety of 3D printing solutions tailored to meet the needs of various industries. Whether you're exploring 3D printer machine prices in India or looking for high-quality 3D printer resins, our range of products is designed to deliver both quality and affordability.

Explore our collection of FDM, SLA, DLP, and SLM printers to find the perfect machine for your project. Whether you’re a hobbyist or an industry expert, our affordable 3D printers empower you to bring your ideas to life.

Here’s a quick breakdown of the most common 3D printer machine prices in India:

- FDM printers: Starting from INR 20,000, these are the most affordable options, ideal for educational institutions and small businesses.

- SLA/DLP printers: With prices ranging between INR 40,000 to INR 1 lakh, these are mid-range printers suitable for professionals who need detailed prints and smooth surface finishes.

- SLM printers: The most expensive option, with prices starting at INR 10 lakh, are used for industrial manufacturing of metal parts.

While initial costs may vary, it’s important to factor in the cost of consumables like filament, resin, or metal powder when budgeting for 3D printing.

At Protomont Technologies, we take pride in offering a wide range of 3D printing solutions tailored to meet diverse industry needs. From precision dental models to large-scale industrial parts, the strength of 3D printers lies in their ability to transform design concepts into functional, high-quality products. In this article, we’ll explore the strengths of different 3D printer types — FDM, SLA, DLP, and SLM — and how they cater to specific applications. We’ll also touch on the 3D printer price in India and the factors influencing the overall 3D printer machine price in India.

- FDM (Fused Deposition Modeling): Affordability Meets Versatility

FDM printers are among the most widely used 3D printers due to their cost-effectiveness and versatility. These printers work by melting and extruding filament layer by layer to build objects. Here’s why FDM printers stand out:

- Affordability: FDM printers are some of the most budget-friendly machines available, making them accessible to hobbyists, educational institutions, and small businesses.

- Material Compatibility: FDM printers can print with a wide range of materials, including PLA, ABS, and PETG, allowing for flexibility in producing parts with different properties.

- Ease of Use: FDM printers are user-friendly, making them a great choice for beginners. Their popularity has also led to a broad support community for troubleshooting and upgrades.

For those looking to explore 3D printer price in India, entry-level FDM models can start as low as INR 20,000, providing a great solution for startups and enthusiasts.

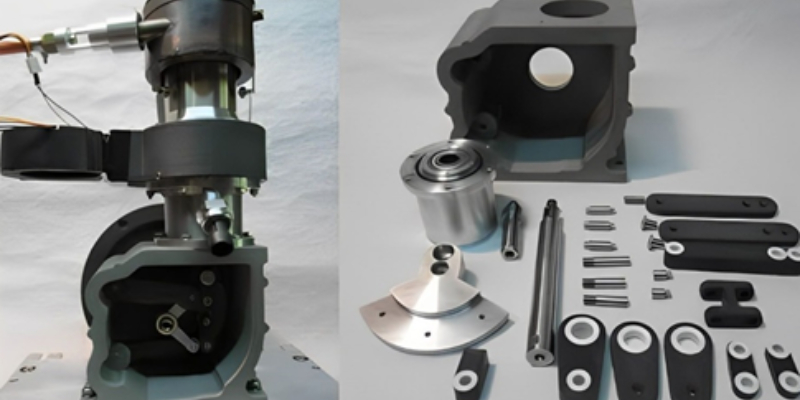

- SLA (Stereolithography): Precision and Surface Quality

SLA 3D printers use a UV light source to cure liquid resin into solid parts. This process results in incredibly detailed and smooth prints, making SLA printers perfect for applications requiring intricate designs. Here are the key strengths of SLA printing:

- High Precision: SLA technology delivers exceptional accuracy and surface finish, which is ideal for creating detailed prototypes, jewelry, and dental models.

- Fine Detail: With SLA printers, you can achieve designs that require fine details that FDM may struggle with, such as tiny features or intricate patterns.

While SLA printers offer higher quality, the 3D printer machine price in India for these models tends to be higher, starting from INR 40,000 to 60,000 for basic units, but the investment pays off in industries like healthcare, dental, and fashion.

- DLP (Digital Light Processing): Speed and Detail Combined

DLP printers work similarly to SLA printers, but instead of a laser, they use a digital light projector to cure the resin. This method enables faster printing times without compromising detail. DLP 3D printers are ideal for applications where speed is crucial, such as:

- Fast Printing: DLP printers excel in printing at higher speeds while maintaining high detail, making them perfect for time-sensitive projects.

- Superior Detail: DLP printers often produce smoother surfaces than FDM and have a competitive edge in sectors like jewelry and dental, where accuracy is essential.

The 3D printer price in India for DLP models starts around INR 60,000 and can rise significantly depending on the model’s capabilities and resolution.

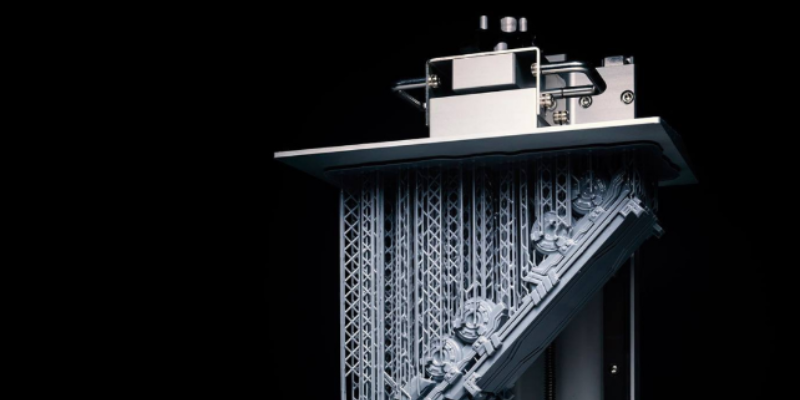

- SLM (Selective Laser Melting): Strength and Durability

SLM 3D printers are at the top tier of 3D printing technology, designed for industrial-grade applications that require the creation of strong, durable metal parts. SLM technology uses a laser to melt metal powders, layer by layer, to create fully dense, functional metal parts. Here’s why SLM stands out:

- Industrial-Grade Strength: SLM printers produce parts with high strength and durability, suitable for critical industries like aerospace, automotive, and medical devices.

- Material Variety: With SLM printing, you can work with metals such as stainless steel, aluminum, and titanium, making it ideal for producing parts that need to withstand high stress or temperatures.

Given their industrial applications, SLM printers are more expensive, with the 3D printer machine price in India starting at INR 10 lakh and upwards. However, the ability to produce functional metal parts often justifies the cost for industries requiring high-performance materials.

Material Costs: What to Expect?

In addition to the 3D printer machine price in India, material costs can vary based on the type of printer and the material used. Here’s a look at the common materials and their costs:

- FDM Filaments: The most common filaments include PLA and ABS, which are affordable and readily available. Prices typically range from INR 1,000 to INR 2,500 per kg.

- SLA/DLP Resins: Resins are more expensive than filaments but offer better surface quality and detail. Expect to pay around INR 2,500 to INR 5,000 per liter, depending on the type of resin.

- SLM Metal Powders: For metal 3D printing, the cost is significantly higher, with prices ranging from INR 10,000 to INR 50,000 per kg, depending on the metal being used.

Despite the higher costs for certain materials, 3D printing in India has become more accessible over the years, allowing businesses to incorporate this technology into their production processes without breaking the bank.

Protomont Technologies: Leading the Way in 3D Printing

At Protomont Technologies, we offer a full range of 3D printers to suit every need. Whether you’re a hobbyist looking for an affordable FDM printer or an industrial manufacturer in need of a high-performance SLM printer, we have the expertise and products to help you succeed. Our 3D printers are available across major cities like Pune, Mumbai, Hyderabad, and Bangalore, ensuring that you have access to the latest technology no matter where you are.