MELT SLM M300 Industrial SLM 3D Printer: Revolutionizing Metal 3D Printing Technology

Melt SLM M300 Industrial SLM 3D Printer

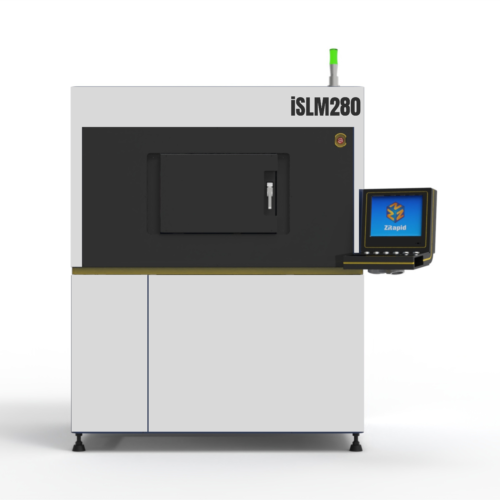

Discover the Melt SLM M300 Industrial SLM 3D Printer, a leading solution in metal 3D printing technology. Engineered for high-performance production, this SLM industrial 3D printer utilizes advanced Selective Laser Melting (SLM) technology to create precision metal parts for various applications, including aerospace, automotive, and medical sectors.

With a generous build volume of 300mm × 300mm × 400mm, the M300 excels in producing high-precision metal components that meet rigorous industry standards. This industrial 3D printer is ideal for rapid prototyping with metal, enabling manufacturers to produce complex geometries with outstanding mechanical properties.

Key Features of Melt SLM M300 Industrial SLM 3D Printer:

- Advanced Metal SLM Technology: Utilizes Selective Laser Melting (SLM) to print high-quality metal parts with excellent mechanical properties, dimensional accuracy, and high mass density.

- Large Build Volume: Capable of printing large parts with a 300mm × 300mm × 400mm build size, ideal for SLM industrial 3D printers and industrial-grade production.

- Flexible Laser Options: Features optional 500W or 1000W fiber lasers with single and dual laser configurations, enhancing the capabilities of metal 3D printing technology.

- High-Precision Scanning: Incorporates a grating-type digital encoder and adjustable beam spot sizes (05-0.3mm), ensuring high scanning accuracy in SLM industrial 3D printers.

- Efficient Powder Circulation System: Supports up-feeding and two-way powder spreading, ensuring consistent powder distribution for uninterrupted production in metal 3D printing.

- Robust Filtration and Shielding: Equipped with a 9% efficient filter system for particles above 0.5 microns, and gas shielding with argon or nitrogen for protection during high-temperature processes in additive manufacturing for metal.

- Versatile Material Compatibility: Prints with a wide range of metals, including stainless steel, titanium, die steel, aluminum, and cobalt-chromium alloys, catering to various industrial 3D printing

- FastLayer Software: Streamlines model processing and slicing with easy layout options, automatic repairs, and parameter selection, perfect for high-performance industrial 3D printing.

- Multiple Scanning Modes: Offers various scanning strategies like checkerboard, honeycomb, and octagonal grids, providing flexibility in meeting different manufacturing requirements for SLM industrial 3D printers.

- User-Friendly Control: Integrated FastFab control software with process guidance and online monitoring enhances workflow efficiency and quality control, making it a top choice for metal 3D printing technology.

Explore our 3D printer online store to learn more about the Melt SLM M300 Industrial SLM 3D Printer and discover how it can transform your production processes today!

Auxiliary Equipment

Industrial Chiller: In metal additive manufacturing, lasers or electron beams used for melting the metal powder generate substantial heat. Chillers help dissipate this heat to prevent damage and maintain performance. It ensures the longevity and reliability of the printer.

Vacuum Drying Oven: a vacuum drying oven removes moisture and contaminants from metal powders and printed parts by creating a low-pressure environment. This process ensures optimal powder flow and prevents defects in the final parts. It helps maintain material quality and print consistency.

Inert Gas Sieving Machine: an inert gas sieving machine cleans and refines metal powders by removing contaminants and moisture in a controlled environment. It ensures consistent particle sizes and prevents oxidation, maintaining powder quality. This enhances the performance and reliability of the printing process, leading to better final part quality.

Galvanometer Calibrator: a galvanometer calibrator is used to ensure precise alignment and calibration of the laser scanning system. It measures and adjusts the accuracy of the galvanometer mirrors that direct the laser or electron beam. Proper calibration is essential for achieving consistent and accurate part dimensions.

Heat Treatment Furnace: A heat treatment furnace is used to alter the mechanical properties of printed parts through controlled heating and cooling. It relieves residual stresses, improves strength, and enhances material properties. This process ensures the final parts meet desired performance and durability standards.

Explosion Proof Vacuum Cleaner: An explosion-proof vacuum cleaner safely collects and contains metal powder and debris, reducing the risk of fires or explosions due to the flammable nature of metal dust. It ensures a clean and safe working environment. This equipment helps maintain operational safety and prevents contamination.

MELT Software

Build Preparation Software: Materialise Magics

Printing Software: Fastlayer

Control Software: Fast Fab (Build in software in machine)

Building volume : 300mmx300mm×400mm

Hot bed temperature : 0-200°C

Powder spreading method : Up-feeding and two-way powder spreading

Equipment power : 6KW

Power supply type : 380V three-phase NPE

Laser type : Fiber laser

Laser power : Optional 500W or 1000W (single and double laser optional)

Scanner type : Grating type high-precision digital encoder vibrating mirror

Beam spot : 0.05-0.3mm adjustable

Scanning speed : 0-7m/s

Gas shield : Argon and nitrogen 0.5-1.5L/min

Circulatory system : 0-1.5m³, air curtain protection

Powder spreading layer thickness : 0.02-0.08mm

Filter system : > 0.5 micron particle filtration efficiency is 99.9% (permanent filter element

can be upgraded)

Scanning mode : Checkerboard grid, honeycomb hexagonal grid, octagonal grid, strips, parallel lines, etc.

Z axis resolution : 1μm

Scanning accuracy : The scanning repetitive positioning accuracy is ≤ 2 µ rad; Linearity 99.9%, range 20%, proportional drift: 8PPM/°C

Printable material : Stainless steel, titanium alloy, die steel, cobalt-chromium alloy, aluminum alloy and other metal materials.

Model processing software : FastLayer supports STL model processing, model layout and transformation, and automatically repairs the model.

Slicing software : FastLayer, support thickness 0.02-0.1mm, material parameter library, multiple scanning modes selection, parameter library development.

Control software : FastFab, with hierarchical control, process guidance and online monitoring.