Anycubic Kobra 3 Max 3D Printer – Ultra-Large, High-Speed 3D Printer for Professionals

₹69,999.00 Incl. of all taxes

Anycubic Kobra 3 Max – Key Feature:

-

Large Build Volume: 420 × 420 × 500 mm for expansive, high-detail prints

-

Advanced Auto-Leveling: LeviQ 3.0 system with anti-step-loss technology

-

High-Speed Printing: Speeds up to 600 mm/s for faster production

-

Enhanced Software Experience: Powered by Anycubic Slicer Next and upgraded mobile app support

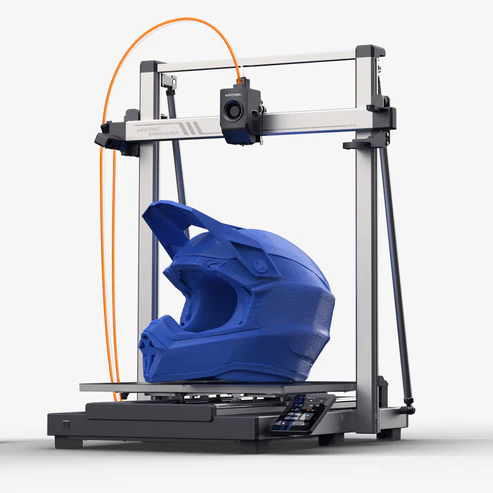

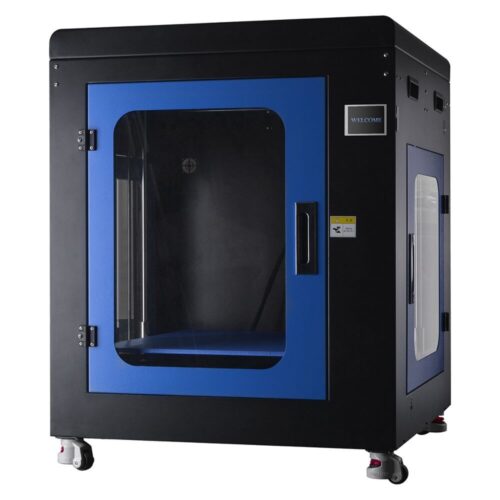

The Anycubic Kobra 3 Max is a next-generation FDM 3D printer engineered for large-scale, high-speed, and precision printing. Designed with a massive 420 × 420 × 500 mm build volume, this printer enables users to create ultra-large models in a single print, significantly reducing assembly requirements and material waste.

With a maximum print speed of 600mm/s, LeviQ 3.0 Auto-Leveling, and AI-powered print monitoring, the Anycubic Kobra 3 Max is an ideal choice for professionals, businesses, and enthusiasts who demand efficiency, reliability, and cutting-edge technology.

Key Features

1. Ultra-Large Print Volume for High-Scale Printing

-

Massive 420 × 420 × 500 mm³ build area, allowing for the creation of large, single-piece models.

-

The print space is equivalent to two carry-on suitcases, ideal for functional prototypes, cosplay, and industrial applications.

-

Reduced filament waste by minimizing the need for assembling smaller parts.

2. High-Speed Printing with Advanced Motion Control

-

Maximum Print Speed: 600mm/s, ensuring rapid production.

-

Enhanced Motion Stability:

-

Dual-Y-axis motor eliminates layer misalignment for higher print accuracy.

-

Anti-Skip Semi-Automatic Belt Tensioning maintains consistent motion precision.

-

-

One-Click Resonance Compensation eliminates unwanted vibrations.

-

Dynamic Flow Compensation ensures consistent extrusion for smooth and detailed prints.

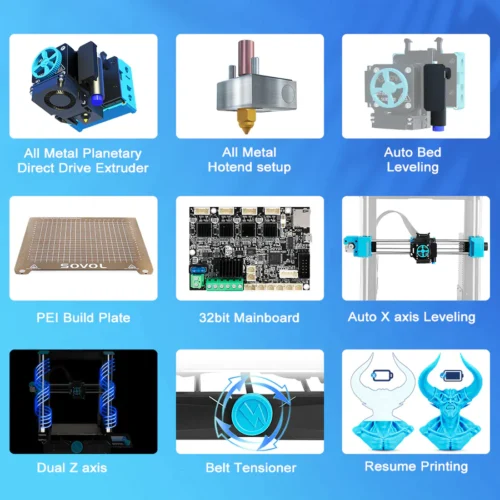

3. Advanced Auto-Leveling and Z-Axis Calibration

-

LeviQ 3.0 Auto-Leveling automatically calibrates the print bed for optimal adhesion.

-

Z-Axis Offset Adjustment allows fine-tuning of the first layer.

-

Precise Layer Alignment enhances overall print consistency and surface finish.

4. Smart Filament Management System

-

Multi-Filament Intelligent Drying ensures filament remains moisture-free for optimal print quality.

-

Filament Auto-Refill automatically loads new filament when a spool runs out.

-

Filament Anti-Entanglement System prevents printing failures caused by filament snags.

5. High-Temperature Hotend for Versatile Material Compatibility

-

300°C High-Temperature Hotend, supporting a wide range of engineering-grade materials.

-

Aerospace-Grade Ceramic Composite Throat Tube provides superior heat resistance and prevents clogs.

-

Quick-Release Hotend Design allows for fast nozzle swaps and maintenance.

-

Dual-Spring Nozzle Assembly ensures precise filament extrusion.

6. AI-Powered Print Monitoring and Smart Features

-

AI Spaghetti Detection identifies and pauses failed prints to prevent material waste.

-

Skip Objects Function automatically removes failed sections from prints, increasing efficiency and reducing cost.

-

Power-Loss Resume ensures the printer continues from the last position after a power outage.

7. Upgraded Software Ecosystem for Seamless Workflow

-

Anycubic Slicer Next, based on OrcaSlicer+, provides LAN Mode and Multi-Plate Management for remote slicing and control.

-

Anycubic App offers real-time monitoring, remote print control, and time-lapse photography.

-

MakerOnline features a vast library of pre-optimized 3D models, enabling one-click slicing and printing.

Anycubic Kobra 3 Max

Build & Dimensions

-

Build Volume: 420 × 420 × 500 mm

-

Machine Dimensions: 706 × 640 × 753 mm

-

Machine Weight: 19 kg

-

Package Weight: 22.5 kg

Printing Performance

-

Recommended Print Speed: 300 mm/s

-

Maximum Print Speed: 600 mm/s

-

Leveling System: LeviQ 3.0 – Fully automatic, no Z-axis compensation required

-

Maximum Nozzle Temperature: 300°C

-

Maximum Heated Bed Temperature: 90°C

-

Operational Noise Level: ≤ 60 dB

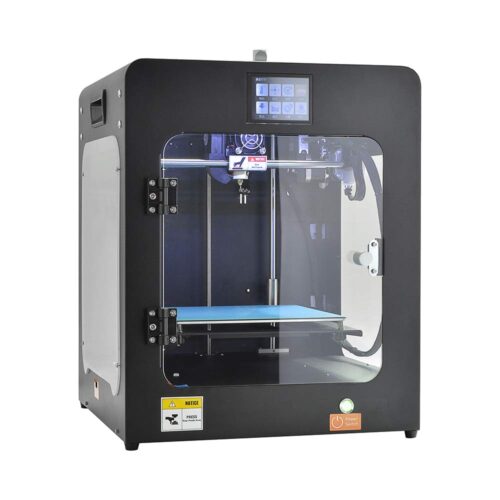

Mechanical Structure

-

X-Axis: Dual shaft core with SG15 bearings

-

Y-Axis: Dual shaft core with SG15 bearings, dual motor drive

-

Z-Axis: Dual motor with dual lead screws

-

Extrusion System: Direct short-distance extrusion

-

Build Surface: Flexible PEI-coated spring steel

Material Compatibility

-

Recommended: PLA, PETG, TPU

-

Supported: ABS, ASA

-

Not Recommended: PA, PC

Software & Connectivity

-

Touchscreen Interface: 4.3-inch color display

-

Slicing Software: Anycubic Slicer Next (third-party slicer compatible)

-

Connectivity Options: Wi-Fi, AC Cloud, LAN