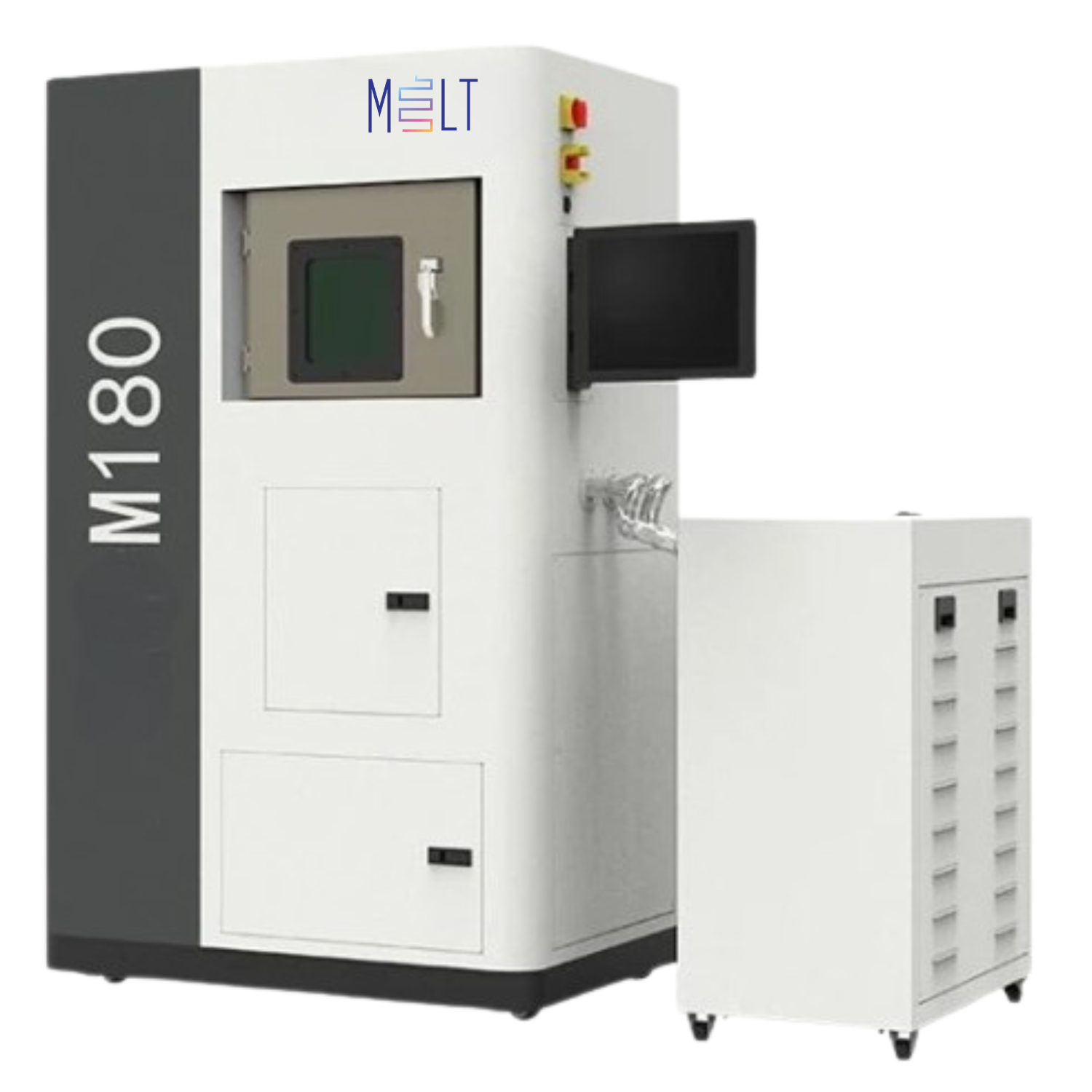

MELT SLM M180 Industrial SLM 3D Printer – High-Precision Metal 3D Printing for Industrial Applications

The MELT SLM M180 Industrial SLM 3D Printer is a high-performance machine designed for Selective Laser Melting (SLM) metal 3D printing. It enables the production of intricate, high-precision parts using Co-Cr alloys, titanium alloys, and pure titanium, making it ideal for industries like dental, aerospace, and automotive. Featuring a dual-laser system with 1000W power and ±0.05mm dimensional accuracy, it ensures fast and reliable additive manufacturing.

With a user-friendly touchscreen interface and automatic typesetting, the M180 offers efficiency and accuracy, making it perfect for rapid prototyping and mass production. If you’re looking for an industrial metal 3D printer with competitive pricing, especially in India, the M180 provides an ideal solution for 3D printing with metal.

Key Features of Melt SLM M180 Industrial 3D Printer :

- Print Volume: Diameter 180mm and height 100mm, perfect for high-precision metal 3D printing and industrial applications.

- Selective Laser Melting 3D Printer: Equipped with a dual-laser system delivering 1000W power (500W per laser) for fast and accurate results.

- Metal 3D Printing Technology: Supports a range of metals, including Co-Cr alloy, titanium alloy, and pure titanium.

- Industrial Metal Printers: Designed for heavy-duty use, this high-performance industrial 3D printer offers consistent results with a dimensional accuracy of ±0.05mm.

- High-Efficiency Additive Manufacturing for Metal: Utilizes two-way powder spreading with a flexible rubber blade for efficient material handling.

- Rapid Prototyping with Metal 3D Printers: Prints up to 350 fixed internal crowns in 6 hours, with typesetting completed in as little as 5 minutes.

- Water-Cooled System: Ensures stable operation during high-volume printing sessions, ideal for industrial metal printers.

- Protective Gas Support: Operates with nitrogen and argon, ensuring the best conditions for high-precision metal 3D printing with a minimum oxygen content of 0.01%.

- Touchscreen Interface: Offers automatic typesetting and path planning, simplifying the workflow.

This powerful combination of additive manufacturing technology and high-performance industrial 3D printing makes the Melt SLM M180 Industrial SLM 3D Printer an essential tool for businesses in need of industrial metal 3D printers at a competitive price, offering unparalleled efficiency and precision for 3D printing with metal.

Auxiliary Equipment

Industrial Chiller: In metal additive manufacturing, lasers or electron beams used for melting the metal powder generate substantial heat. Chillers help dissipate this heat to prevent damage and maintain performance. It ensures the longevity and reliability of the printer.

Vacuum Drying Oven: a vacuum drying oven removes moisture and contaminants from metal powders and printed parts by creating a low-pressure environment. This process ensures optimal powder flow and prevents defects in the final parts. It helps maintain material quality and print consistency.

Inert Gas Sieving Machine: an inert gas sieving machine cleans and refines metal powders by removing contaminants and moisture in a controlled environment. It ensures consistent particle sizes and prevents oxidation, maintaining powder quality. This enhances the performance and reliability of the printing process, leading to better final part quality.

Galvanometer Calibrator: a galvanometer calibrator is used to ensure precise alignment and calibration of the laser scanning system. It measures and adjusts the accuracy of the galvanometer mirrors that direct the laser or electron beam. Proper calibration is essential for achieving consistent and accurate part dimensions.

Heat Treatment Furnace: A heat treatment furnace is used to alter the mechanical properties of printed parts through controlled heating and cooling. It relieves residual stresses, improves strength, and enhances material properties. This process ensures the final parts meet desired performance and durability standards.

Explosion Proof Vacuum Cleaner: An explosion-proof vacuum cleaner safely collects and contains metal powder and debris, reducing the risk of fires or explosions due to the flammable nature of metal dust. It ensures a clean and safe working environment. This equipment helps maintain operational safety and prevents contamination.

MELT Software

Build Preparation Software: Materialise Magics

Printing Software: Fastlayer

Control Software: Fast Fab (Build in software in machine)

Print volume : Diameter 180mm, height 100mm, round

Baseplate fixing mode : Magnetic attraction fixation

Dimensional accuracy : ±0.05mm

Powder spreading layer thickness : 0.02-0.05mm.

Powder spreading method : Powder feeding and two-way powder spreading

Rubber type : Flexible rubber blade

Maximum single powder addition : 30KG (cobalt chromium powder)

Printable material : Co-Cr alloy, titanium alloy, pure titanium, etc.

Number of lasers : Double laser, supporting single laser work.

Laser power: 1000W (double 500W)

Cooling mode: Water-cooling

Spot size : 50-80µm

Protective gas: Nitrogen and argon

Minimum oxygen content: 0.01%

Power supply type : Three-phase 380V

Average power consumption : 3KW

Scanning speed of galvanometer: 0-7m/s

Typesetting mode: Automatic typesetting and path planning

Mode of operation : Touch screen

Do you support power failure and continuous calling : Be

Do you support stitching printing : Be