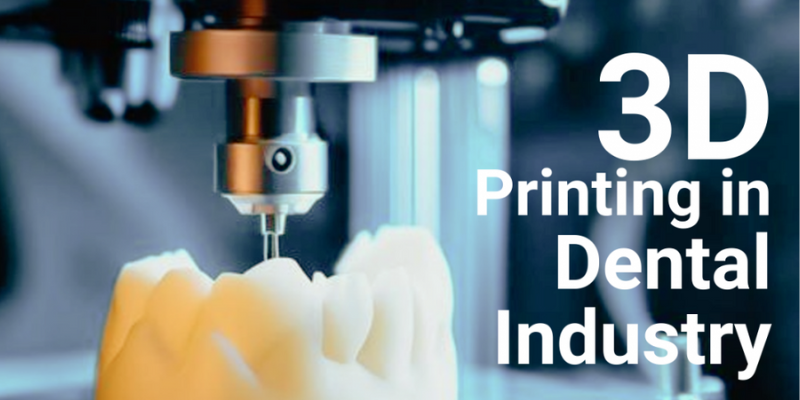

In the field of dentistry, where every smile narrates, dental 3D printing holds the key to revolutionizing patient care with innovation that caters to the needs of the patients. With 3D printing in the game, the industry has been seeing a rapid influx of new innovations, especially related to dental 3D printers. These dental 3D printers for the dental industry provide wide-ranging benefits in terms of crafting dental models, prosthetics, and aligners that are made to fit. Before we dig deeper into the applications of 3D printers in the dental industry, let us give you some nitty-gritty knowledge about Dental 3D printing.

What is Dental 3D printing?

Dental 3D printing uses additive manufacturing technology to manufacture dental parts such as aligners, crowns, and prosthetics. 3D printing works by creating a CAD file of the patient’s oral anatomy and later printing the file by a dental 3D printer, thereby achieving the desired fit of dental models for the patient. Earlier, the creation of implants, moulds and prosthetics for the patient was a tiresome and tough process, however, with the advent of 3D printers, this process has been simplified to a large extent, enhancing the quality of treatment for the patient.

Why do Dental 3D printers appear as the game changers?

It is common knowledge that the processes within the field of dentistry require a dentist’s precision and efficiency. With 3D printers coming into the field, dentists can rely on these machines to provide valuable assistance to their patients without much hassle. Here’s how:

-

- Higher accuracy and efficiency: Models printed by dental 3D printers achieve a better fit, thereby reducing the scope of error in the making process.

-

- Better quality and durability: One of the key advantages of using a 3D printer for dental models is the longevity of the printed teeth. Unlike traditional dental prosthetics, which may wear out over time, 3D-printed teeth are designed to last for years to come.

Versatile Applications of 3D Printer for Dental Models

1. Highly precise dental models and prostheses: 3D printers allow dentists to create complicated dental models and prosthetics with extreme precision, assuring a perfect fit for each patient based on their oral anatomy.

2. Freedom to customize dental models: With 3D printing, dentists may tailor dental equipment such as crowns, bridges, and aligners to each patient’s unique oral anatomy, lowering the possibility of mistake.

3. Improved treatment planning: Dentists can better see and plan treatments with a 3D printer for dental models, resulting in improved results for patients. It also allows dentists to effectively discuss treatment plans with patients.

4. Enhanced patient satisfaction: Customized dental equipment made with 3D printing are more appealing to use, resulting in higher patient satisfaction. Patients value the individualized approach to dental care, which may enhance their entire experience.

5. Streamlined production process for dental labs: 3D printing reduces manual work and production time. This efficiency enables dental labs to make dental models more rapidly and cost-effectively, which benefits both the lab and the patients.

6. Creation of surgical guides: With 3D printers, dentists can create surgical guides for accurate cutting, making dental surgical processes easier.

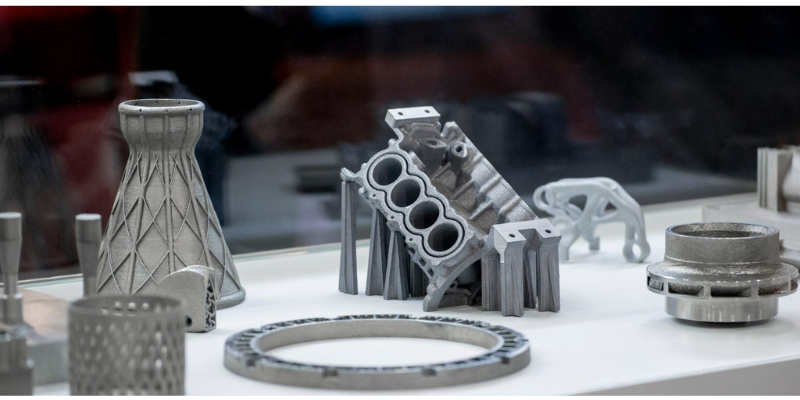

What kind of materials are used in 3D dental industry?

Materials utilized in dental 3D printing differ from those used in other industrial 3D printing applications. Dental 3D printing materials are engineered to be biocompatible and safe for dental applications. Some resins are used in models and replicas, while others are used for the purpose of implantation. There are other resins used to make temporary dental equipment, clear resins for mouth guards, and gingiva-like resins for dental implants. Resins’ chemical compositions vary depending on the producer. Dentists typically choose the material that they believe is suitable for the patient’s dental health.

What are the different types of dental 3D printers used in the industry?

The three most significant types of 3D printers used in the dental industry are the ones which function on technologies such as Digital Light Processing, Material Jetting and Stereolithography. Printers which make use of Digital Light Processing (DLP) technology are used to make dental prosthetics, crowns and aligners as they have a good resolution and comparatively faster rate of production. Printers using material jetting technology have the ability to use multiple materials in the making of complex dental models and prosthetics. Lastly, printers running on Stereolithography provide a smooth finish to the surface of dental models and surgical guides.

The Future of Dentistry

It is evident that 3D printers in the dental industry are being looked upon as the future of dentistry owing to their transformative technology. These printers have revolutionized the dental industry, making oral health more accessible than earlier. And, with its unmatched efficiency, customizability and precision, 3D printing is coming to the fore with an aim for a brighter future in the dental industry.